News &

Inspiration.

Stay updated with the latest trends in corporate gifting, ESG initiatives, and employee wellbeing strategies.

Customization Process

Customization ProcessWhy Adding Foil Stamping + Embossing to Your Corporate Gift Box Doesn't Add 3 Days—It Adds 3 Weeks

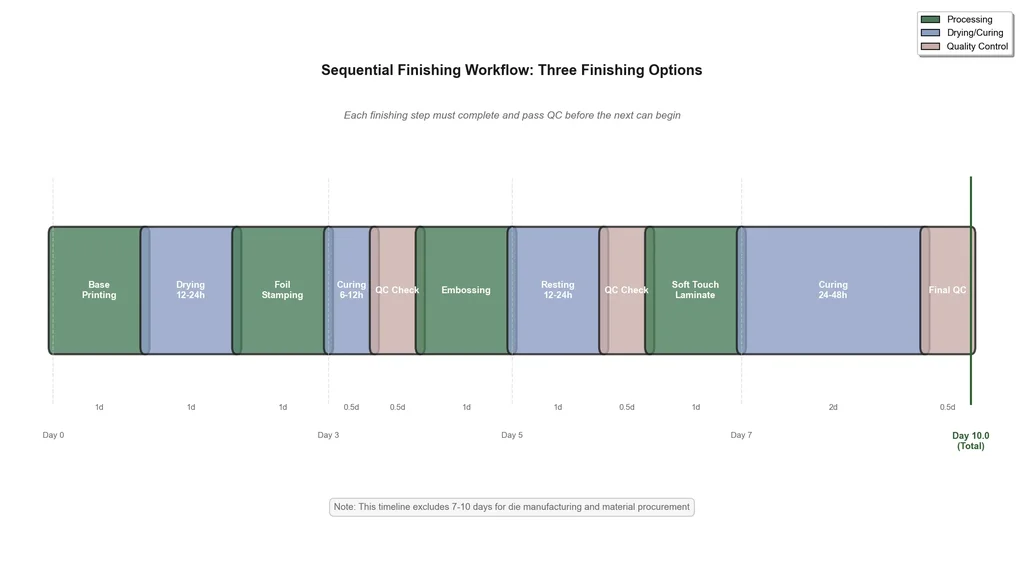

When procurement teams specify multiple finishing options for custom corporate gift boxes—foil stamping for the logo, embossing for the brand name, soft touch laminate for the texture—they typically assume each finishing option adds 1-2 days to the production timeline. In practice, the relationship between number of finishing options and total lead time is non-linear, because each finishing technique requires sequential processing, separate tooling, dedicated drying time, and independent quality control checkpoints.

Read Article Customization Process

Customization ProcessWhy Your Packaging Supplier's MOQ Isn't Negotiable Like You Think

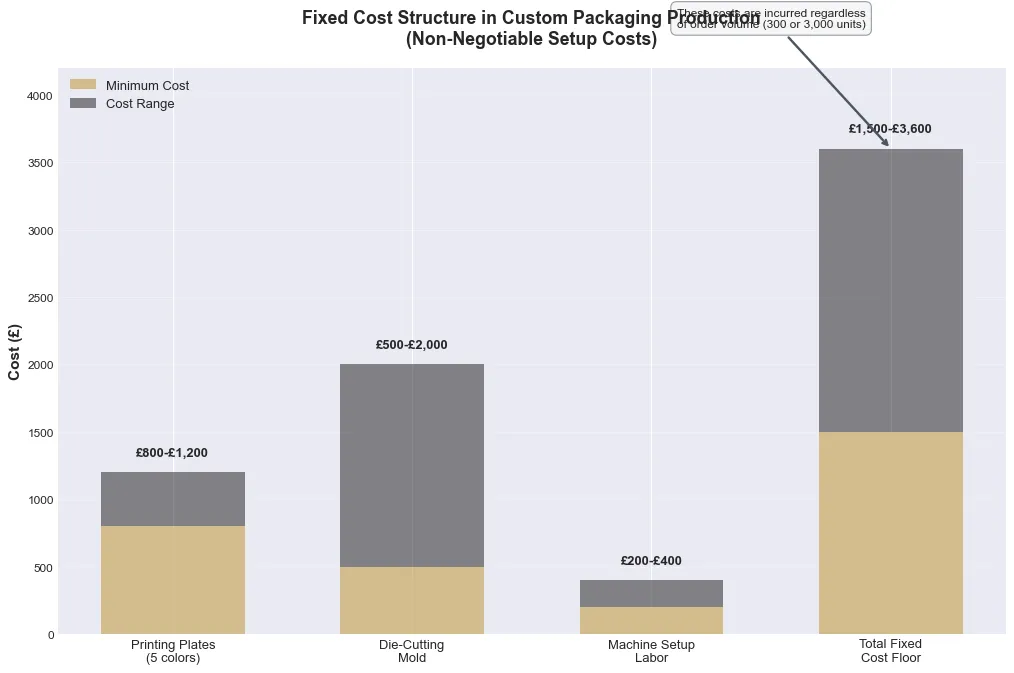

Procurement teams routinely approach supplier MOQ requirements as if they were pricing negotiations—offering to pay a premium per unit in exchange for a lower minimum order quantity. This misjudgment stems from treating MOQ as a profit margin lever when it's actually a production constraint floor determined by fixed tooling costs, material sourcing minimums, and operational efficiency thresholds.

Read Article Customization Process

Customization ProcessWhy Your Brand Colour Specification Fails Between Digital Approval and Physical Corporate Gift Box Production

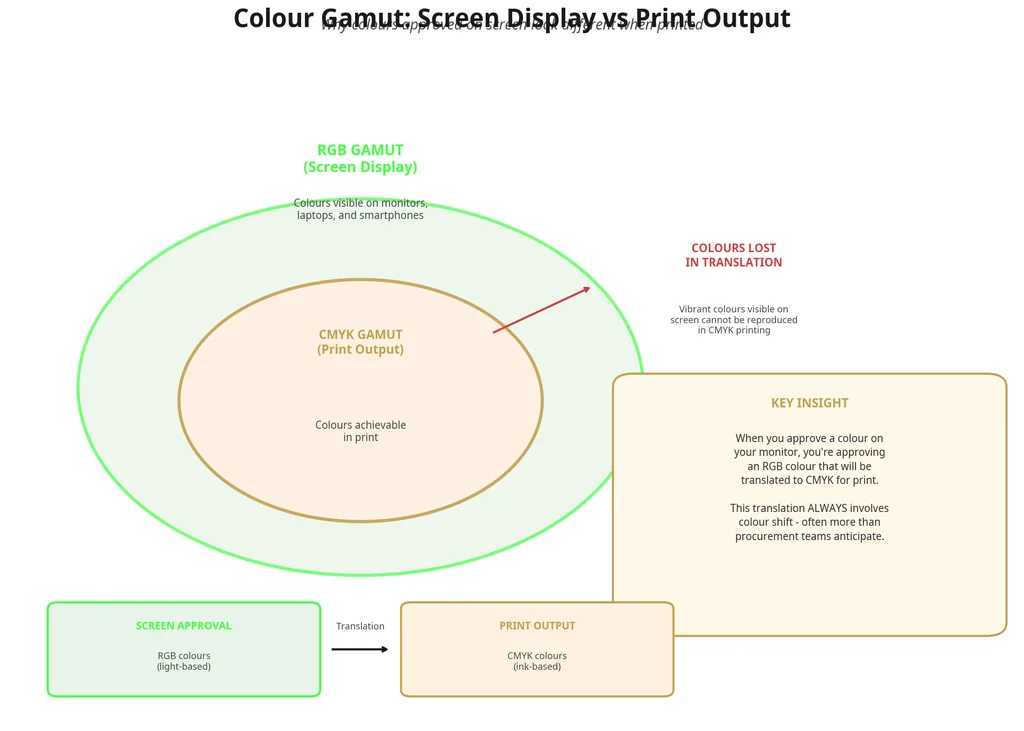

When procurement teams approve a corporate gift box design on screen, they're viewing an RGB representation of what will ultimately be printed in CMYK or Pantone inks. The colour they see on their monitor is fundamentally different from the colour that will appear on the physical packaging—and this gap is where colour specification failures begin.

Read Article Customization Process

Customization ProcessWhy Your 200-Unit Corporate Gift Box Order Gets Quoted at 3x the Expected Unit Price

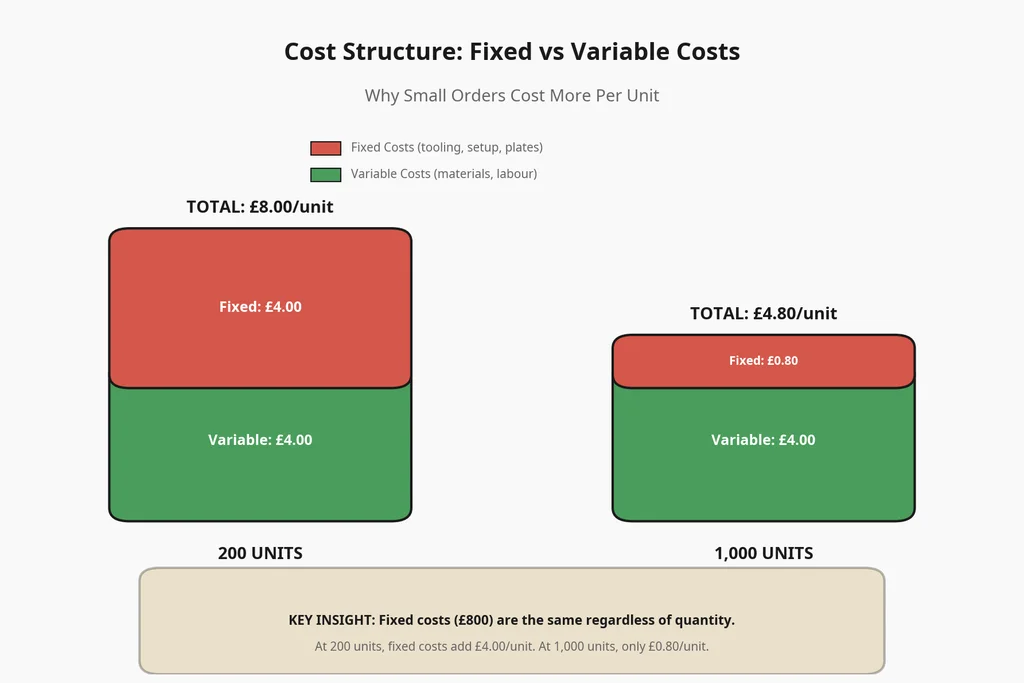

When procurement teams request quotes for custom corporate gift boxes, there's a common assumption that unit pricing scales linearly with quantity. The reality is that customization costs have a fixed cost floor that makes small orders disproportionately expensive—and this gap between expectation and reality is where budget misjudgments begin.

Read Article Customization Process

Customization ProcessWhy Your Approved Corporate Gift Box Sample Won't Match Mass Production

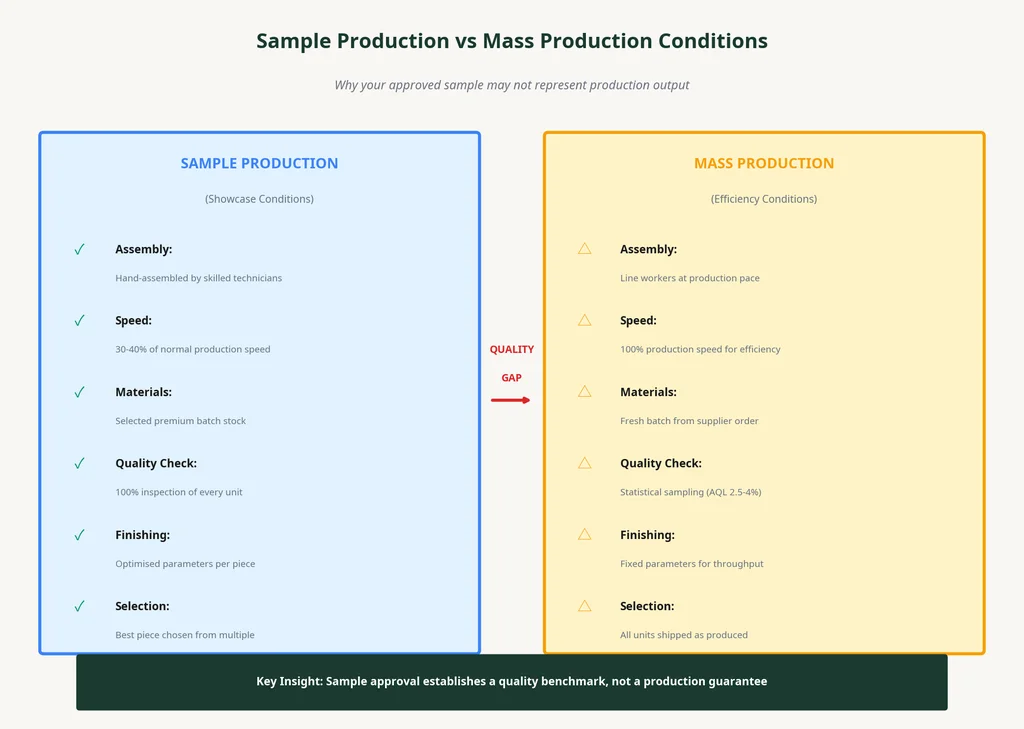

When procurement teams approve a physical sample from their supplier, there's a natural assumption that mass production will deliver identical results. In practice, the gap between 'sample approved' and 'production delivered' exists because of fundamental differences in how samples and production runs are manufactured—differences that are rarely disclosed during the approval process.

Read Article Customization Process

Customization ProcessWhy 'Minor Design Changes' Reset Your Corporate Gift Box Production Timeline

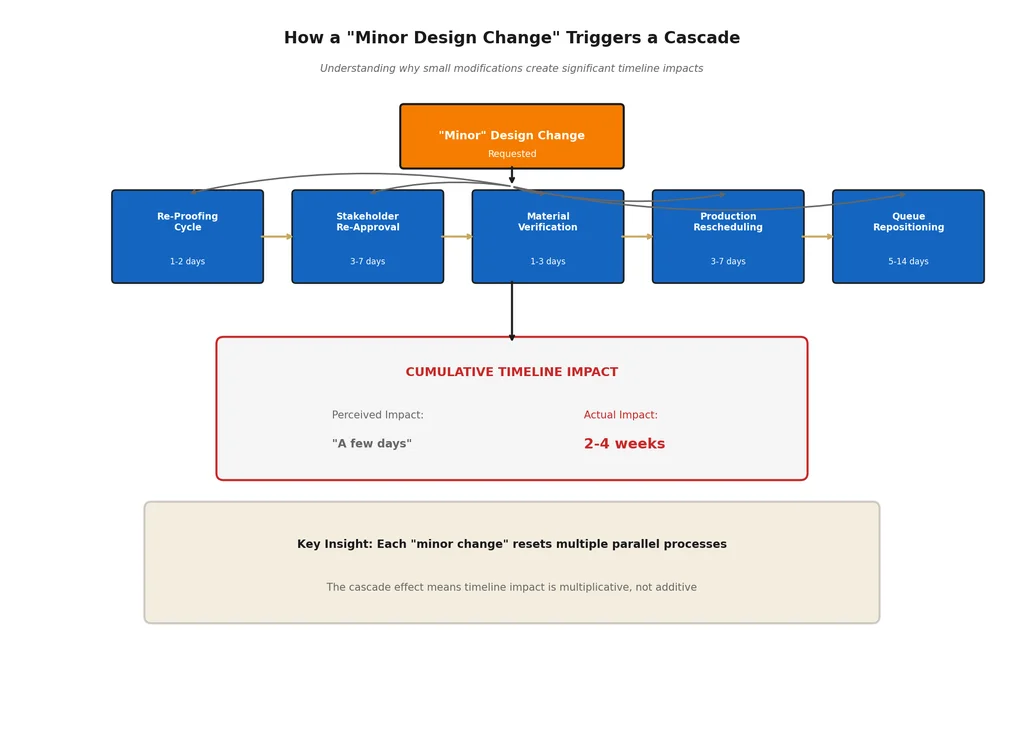

When procurement teams request a small adjustment to an approved design-a logo resize, a colour tweak, a text addition-there's a natural assumption that the change will add a few days to the timeline at most. In practice, what appears to be a minor modification triggers a cascade of re-approvals, material re-verification, and production queue repositioning that can add 2-4 weeks to the delivery date.

Read Article Customization Process

Customization ProcessWhy 'Design Approved' Doesn't Mean Production Can Start on Your Corporate Gift Boxes

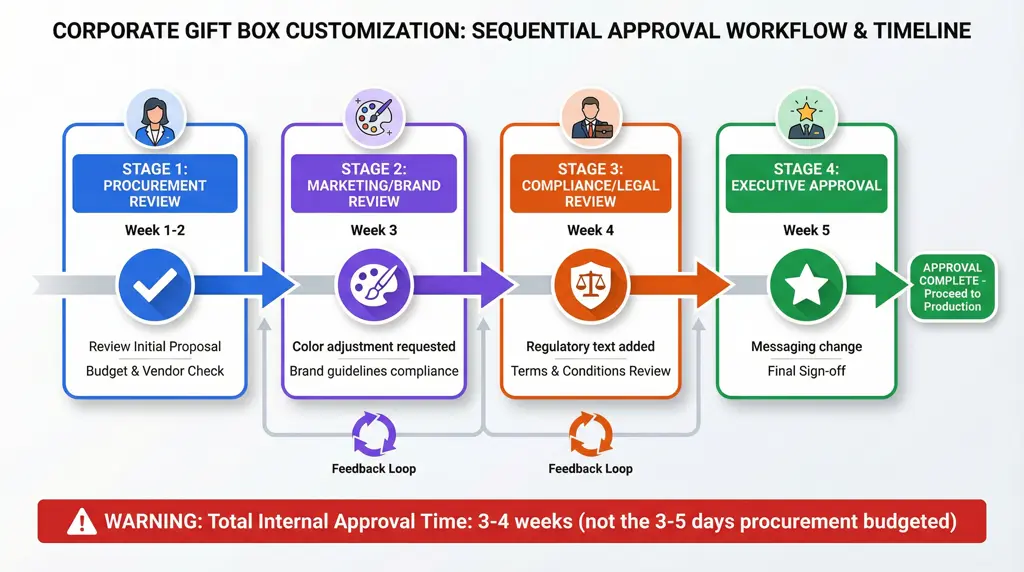

When procurement teams receive design approval confirmation from their supplier, there's a natural assumption that production will begin immediately. In practice, the gap between 'design approved by procurement' and 'production started' exists because of internal stakeholder alignment—specifically, the sequential approval process that occurs after the initial design is finalized.

Read Article Lead Time

Lead TimeWhy Your 'Approved' Corporate Gift Box Design Isn't Cleared for UK/EU Production

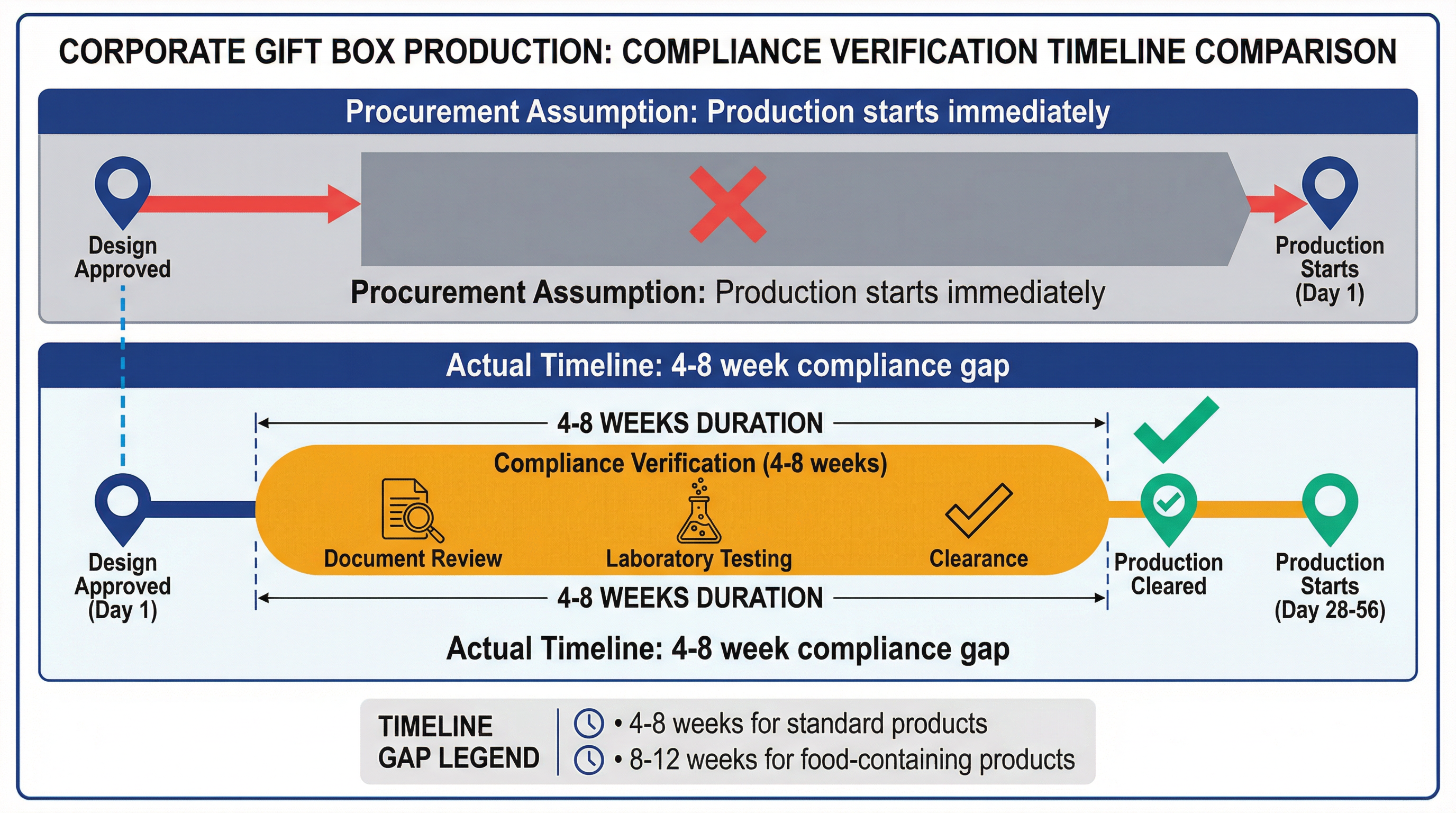

When procurement teams receive design approval from their internal stakeholders, there's a natural assumption that production can begin immediately. In practice, the gap between 'design approved' and 'production cleared' exists because of regulatory compliance verification—specifically, the requirement to verify that packaging materials, food contact surfaces, and product components meet UK/EU market requirements before production commences.

Read Article Lead Time

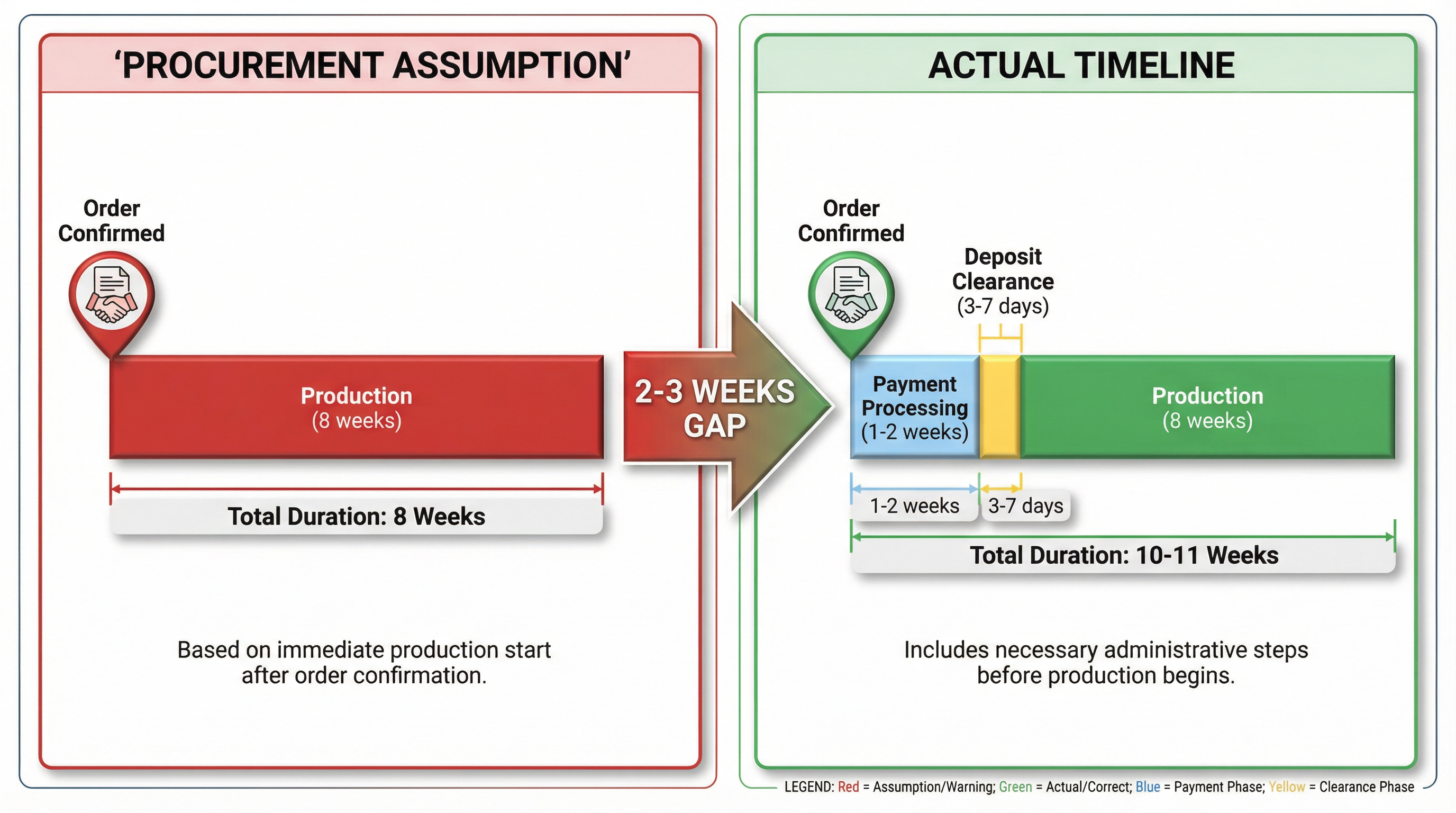

Lead TimeWhy 'Order Confirmed' Doesn't Mean Production Starts on Your Corporate Gift Boxes

When procurement teams issue a purchase order and receive supplier confirmation, there's a natural assumption that production begins immediately. In practice, the gap between 'order confirmed' and 'production started' exists because of payment terms—specifically, the requirement for deposit payments before production commences.

Read Article Lead Time

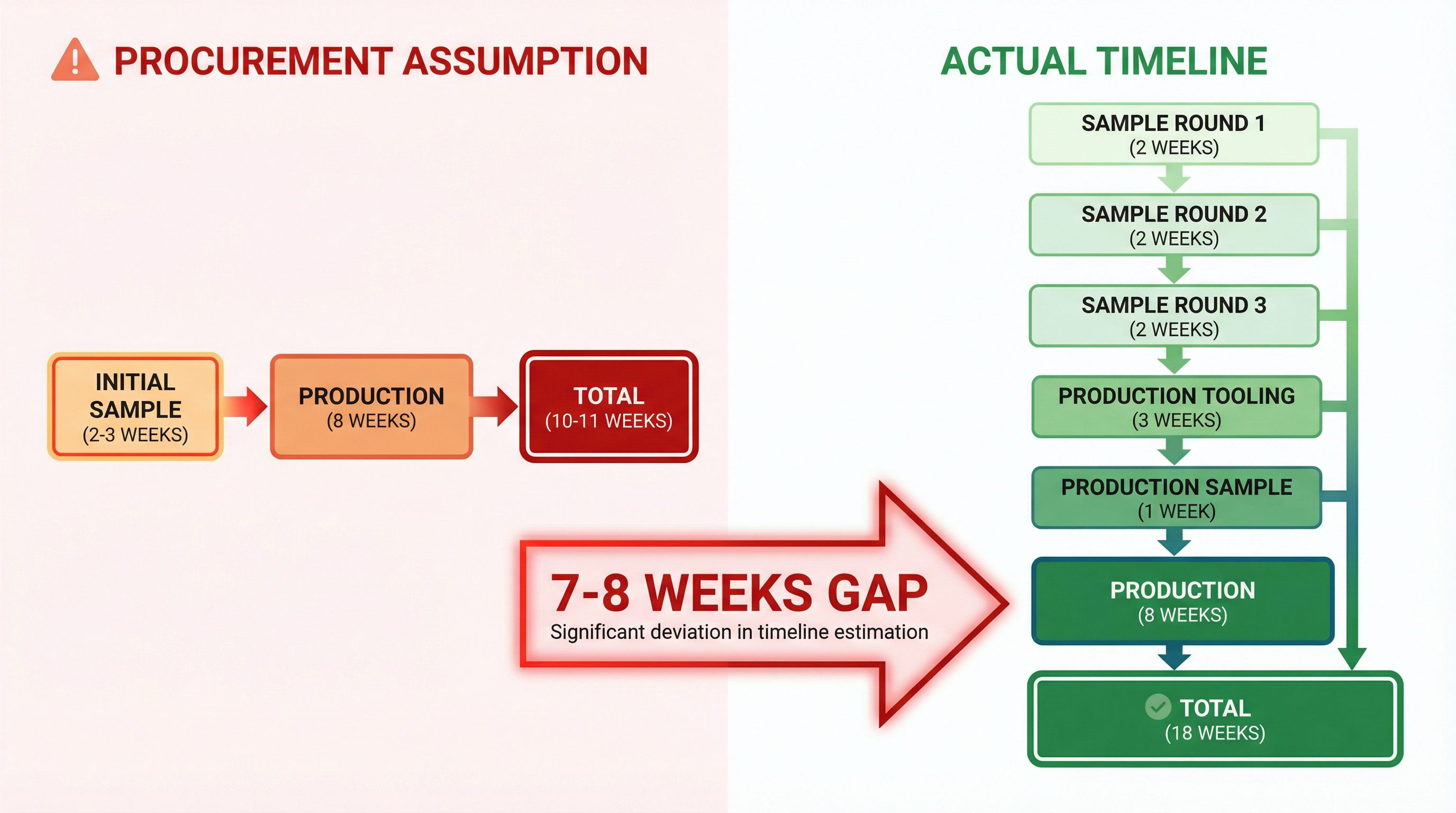

Lead TimeWhy Each 'Minor Tweak' to Your Corporate Gift Box Sample Adds Weeks, Not Days

Procurement teams often budget for a single 2-3 week sample cycle, but multiple revision rounds can extend the pre-production phase by 6-12 weeks. Each 'minor tweak' requires complete tooling recreation, not simple adjustments.

Read Article LEAD TIME

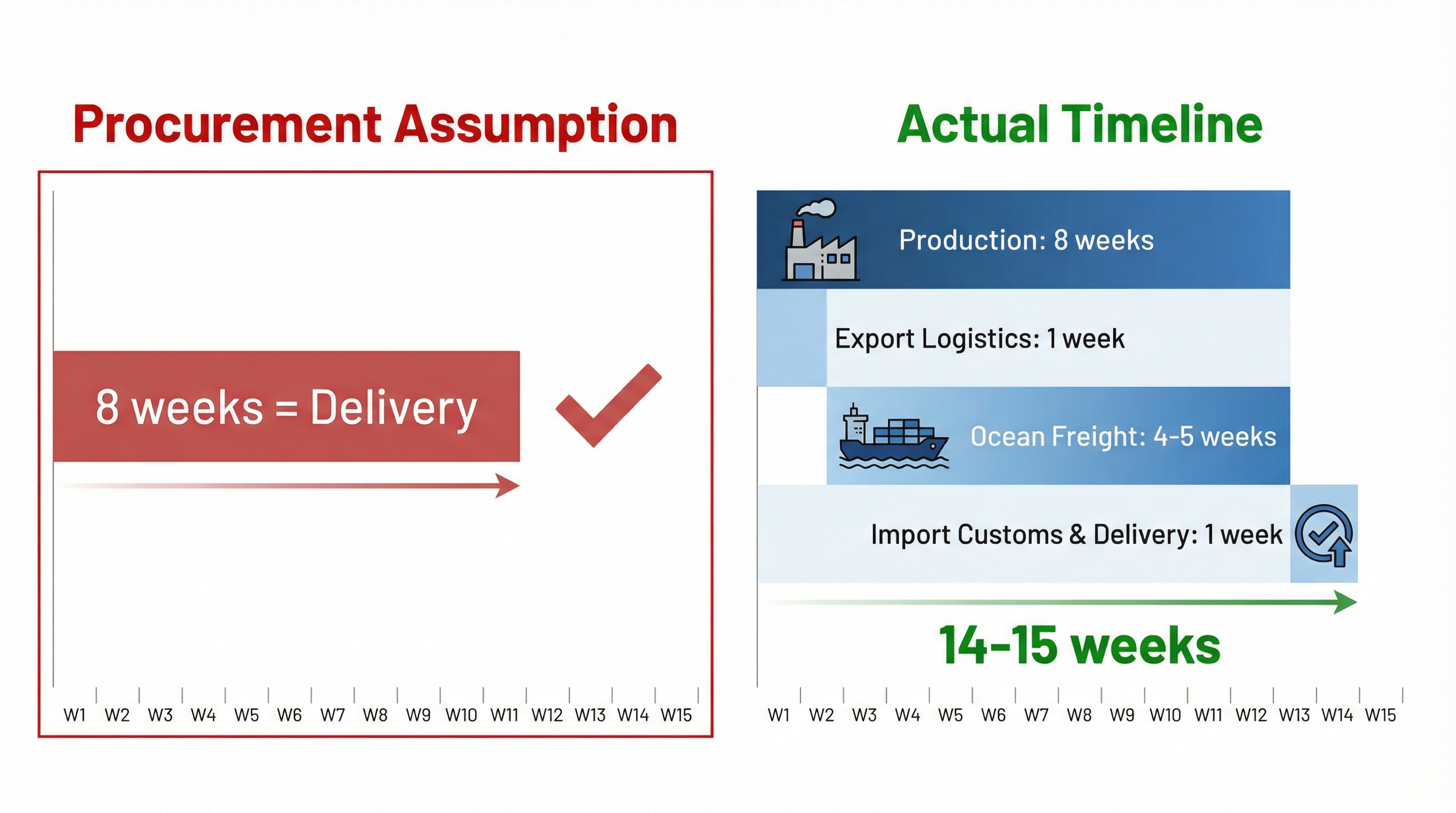

LEAD TIMEWhy 'Production Complete' Doesn't Mean Your Corporate Gift Boxes Are Ready to Distribute

Procurement teams often treat 'production complete' as the delivery date, failing to account for the 4-8 week shipping and logistics phase that occurs after manufacturing ends.

Read Article Lead Time

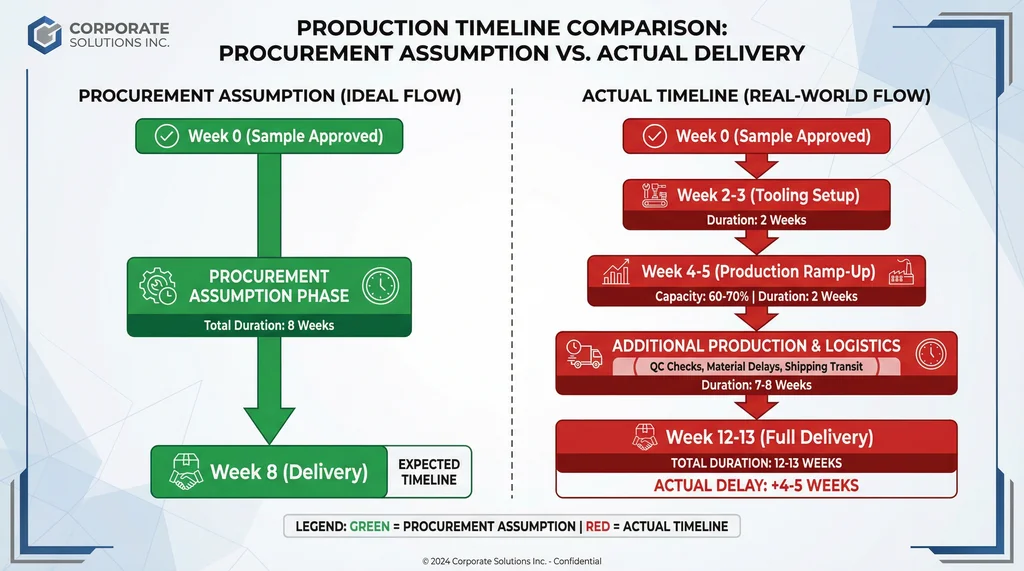

Lead TimeWhy Your Production Doesn't Start Immediately After Sample Approval

The gap between sample approval and full production is often underestimated, extending lead times by 2-4 weeks through tooling setup and production ramp-up phases.

Read Article