Back to BlogCustomization Process

Why 'Minor Design Changes' Reset Your Corporate Gift Box Production Timeline

2026-01-27

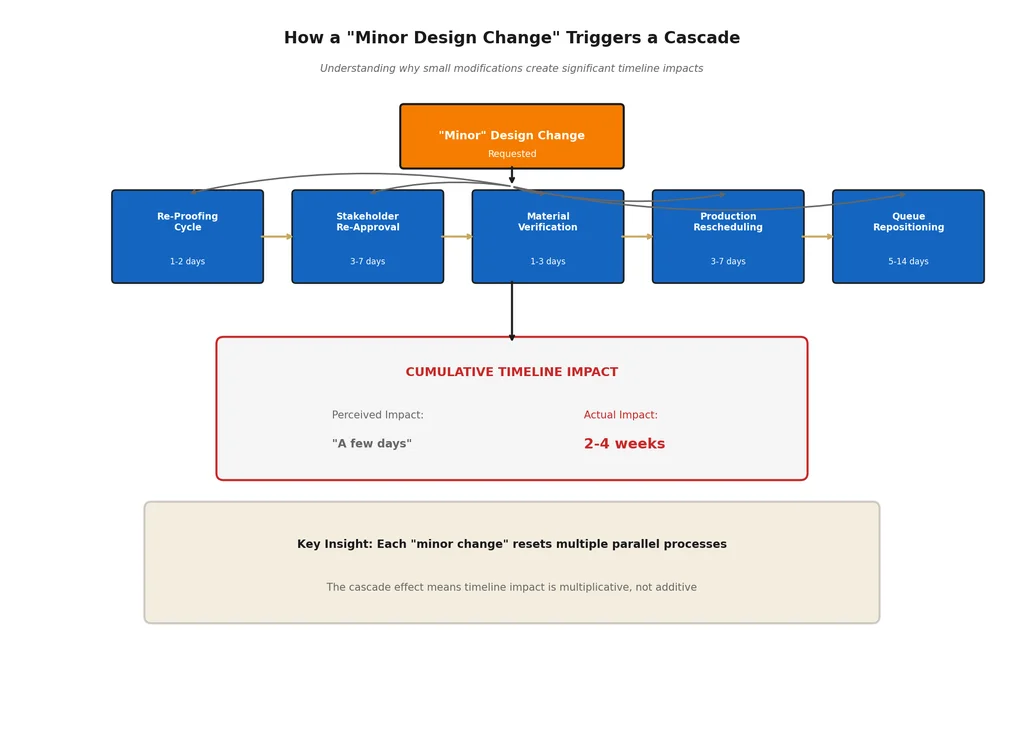

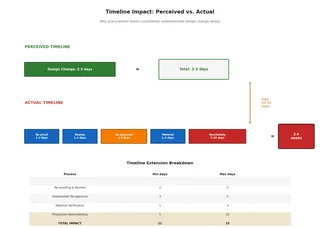

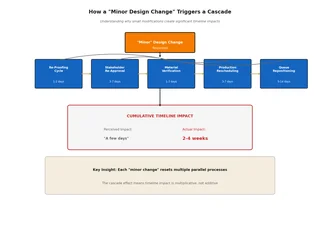

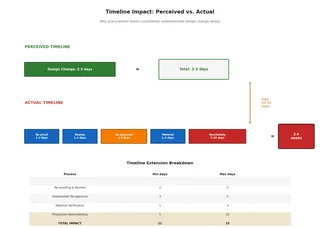

When procurement teams request a small adjustment to an approved design-a logo resize, a colour tweak, a text addition-there's a natural assumption that the change will add a few days to the timeline at most. The design has already been approved, the supplier has already prepared for production, and the change seems trivial. A logo that needs to be 5% larger, a Pantone shade that needs to shift slightly warmer, an additional line of regulatory text-these feel like corrections that should take hours, not weeks. In practice, what appears to be a minor modification triggers a cascade of re-approvals, material re-verification, and production queue repositioning that can add 2-4 weeks to the delivery date. The disconnect between the perceived simplicity of the change and its actual timeline impact is one of the most common sources of project delay in custom corporate gift box production.

The misjudgment begins with how procurement teams conceptualise design changes. From the buyer's perspective, a design change is a modification to a digital file-the supplier opens the file, makes the adjustment, saves it, and moves on. The time required is measured in minutes or hours, depending on the complexity of the change. The assumption is that once the file is updated, production can resume from where it left off. From the supplier's perspective, a design change is not simply a file modification-it's a trigger for a complete re-validation of the production plan. The supplier must regenerate print files, create new proofs, obtain fresh approvals from all stakeholders, verify that materials on hand are still compatible with the revised design, and potentially reschedule production capacity. Each of these steps takes time, and the cumulative effect is measured in weeks, not days. The supplier is not being slow or inefficient-they are following standard manufacturing protocols that exist to prevent costly errors downstream.

The re-proofing cycle is the first source of timeline extension. When a design change is requested, the supplier must create a new design proof that reflects the modification. This proof must be reviewed and approved by the procurement team before any production-related work can continue. The proof creation process itself takes 1-2 business days, depending on the supplier's workload and the complexity of the change. The procurement team then needs time to review the proof-typically 1-3 business days, depending on stakeholder availability. If the procurement team identifies additional issues during the review, another revision cycle begins. Industry data suggests that packaging projects undergo an average of 12-18 revision rounds from concept to market, with each round involving colour adjustments, copy optimisation, and regulatory label updates. A "minor change" that triggers even one additional revision round adds 3-5 business days to the timeline. If the change triggers feedback from multiple stakeholders-marketing wants a different colour, compliance wants different text placement-the timeline extension compounds.

The stakeholder re-approval requirement is often invisible to the procurement team requesting the change. When the original design was approved, it was approved by multiple stakeholders-procurement, marketing, compliance, and potentially an executive sponsor. Each of these stakeholders signed off on specific aspects of the design: marketing approved the brand consistency, compliance approved the regulatory text, and the executive sponsor approved the strategic messaging. When a design change is made-even a "minor" one-the supplier cannot assume that the previous approvals still apply. A logo resize might affect the visual balance that marketing approved. A colour tweak might affect the brand consistency that was previously confirmed. A text addition might affect the regulatory compliance that was previously verified. The supplier must obtain fresh approvals from all relevant stakeholders before proceeding, because proceeding without approval creates liability risk. If the production run is completed and a stakeholder later objects to the change, the supplier may be held responsible for producing boxes that were not properly approved.

The material compatibility verification is another source of timeline extension that procurement teams rarely anticipate. When a supplier prepares for production, they order materials based on the approved design specifications. Paper stock is ordered in quantities that match the production volume. Printing plates are created based on the approved artwork. Foil dies are manufactured based on the approved foil placement. Embossing dies are created based on the approved embossing design. When a design change is requested, the supplier must verify that the materials already ordered are still compatible with the revised design. A logo resize might require a new printing plate. A colour tweak might require different ink formulations. A text addition might require reflowing the layout, which could affect the paper stock requirements. If the materials on hand are not compatible with the revised design, the supplier must order new materials-a process that adds 1-2 weeks to the timeline, depending on material availability and supplier lead times.

The production queue repositioning is the most significant source of timeline extension, and it's the one that procurement teams understand least. Suppliers schedule their production capacity weeks in advance, allocating machine time, labour, and finishing capacity to specific projects. When a design change is requested, the supplier cannot simply pause the project and resume it later-they must release the allocated production slot and reschedule the project into a future slot. The original slot is then allocated to another project that is ready for production. When the revised design is finally approved and materials are verified, the supplier must find a new production slot-which may be 1-2 weeks later than the original slot, depending on the supplier's production schedule. The procurement team has not only lost time to the re-proofing and re-approval process-they have lost additional time to production queue repositioning. The cumulative timeline impact of a "minor change" can be 3-4 weeks: 1 week for re-proofing and re-approval, 1-2 weeks for material verification and potential re-ordering, and 1-2 weeks for production queue repositioning.

The stakeholder re-approval requirement is often invisible to the procurement team requesting the change. When the original design was approved, it was approved by multiple stakeholders-procurement, marketing, compliance, and potentially an executive sponsor. Each of these stakeholders signed off on specific aspects of the design: marketing approved the brand consistency, compliance approved the regulatory text, and the executive sponsor approved the strategic messaging. When a design change is made-even a "minor" one-the supplier cannot assume that the previous approvals still apply. A logo resize might affect the visual balance that marketing approved. A colour tweak might affect the brand consistency that was previously confirmed. A text addition might affect the regulatory compliance that was previously verified. The supplier must obtain fresh approvals from all relevant stakeholders before proceeding, because proceeding without approval creates liability risk. If the production run is completed and a stakeholder later objects to the change, the supplier may be held responsible for producing boxes that were not properly approved.

The material compatibility verification is another source of timeline extension that procurement teams rarely anticipate. When a supplier prepares for production, they order materials based on the approved design specifications. Paper stock is ordered in quantities that match the production volume. Printing plates are created based on the approved artwork. Foil dies are manufactured based on the approved foil placement. Embossing dies are created based on the approved embossing design. When a design change is requested, the supplier must verify that the materials already ordered are still compatible with the revised design. A logo resize might require a new printing plate. A colour tweak might require different ink formulations. A text addition might require reflowing the layout, which could affect the paper stock requirements. If the materials on hand are not compatible with the revised design, the supplier must order new materials-a process that adds 1-2 weeks to the timeline, depending on material availability and supplier lead times.

The production queue repositioning is the most significant source of timeline extension, and it's the one that procurement teams understand least. Suppliers schedule their production capacity weeks in advance, allocating machine time, labour, and finishing capacity to specific projects. When a design change is requested, the supplier cannot simply pause the project and resume it later-they must release the allocated production slot and reschedule the project into a future slot. The original slot is then allocated to another project that is ready for production. When the revised design is finally approved and materials are verified, the supplier must find a new production slot-which may be 1-2 weeks later than the original slot, depending on the supplier's production schedule. The procurement team has not only lost time to the re-proofing and re-approval process-they have lost additional time to production queue repositioning. The cumulative timeline impact of a "minor change" can be 3-4 weeks: 1 week for re-proofing and re-approval, 1-2 weeks for material verification and potential re-ordering, and 1-2 weeks for production queue repositioning.

The version control chaos that accompanies design changes creates additional risk and delay. When multiple stakeholders are involved in the approval process, and multiple revision rounds occur, the risk of version confusion increases dramatically. The design team may be working on version 9, while the legal team has just reviewed version 8, marketing is referencing version 7 for promotional materials, and the supplier received version 6. This version misalignment causes duplicate work, conflicting feedback, and additional revision cycles. A procurement team may approve a design change, only to discover that the supplier implemented the change on an outdated version of the file. The change must be re-implemented on the correct version, triggering another proof cycle. These version control issues are not the result of incompetence-they are the predictable consequence of managing complex design projects across multiple stakeholders without centralised version management systems.

The cost implications of design changes extend beyond timeline delays. When a supplier has already ordered materials based on the original design, and a design change renders those materials incompatible, someone must absorb the cost of the wasted materials. If the supplier absorbs the cost, they may increase their pricing on future projects to account for the risk of design changes. If the buyer absorbs the cost, the project budget increases unexpectedly. When a supplier has already created printing plates, foil dies, or embossing dies based on the original design, and a design change requires new tooling, the cost of the original tooling is wasted. These costs are rarely visible in the initial project quotation, because the quotation assumes that the design will be finalised before production begins. When design changes occur after production preparation has started, the hidden costs emerge-and they can be substantial for complex projects with multiple finishing processes.

The practical reality is that design changes after approval should be treated as exceptions, not routine adjustments. When a procurement team is considering a design change, they should ask themselves: "Is this change essential, or is it a preference?" Essential changes-such as correcting a regulatory error or fixing a brand guideline violation-justify the timeline and cost impact. Preference changes-such as making a logo slightly larger because an executive thinks it looks better-may not justify the impact. The procurement team should also ask: "Can this change be incorporated into the next order, rather than this order?" If the change is not essential for the current project, deferring it to a future order avoids the timeline disruption and cost impact entirely.

When planning custom corporate gift box projects, it's essential to build in adequate time for design development and stakeholder alignment before production begins. For comprehensive guidance on structuring realistic timelines that minimise the need for post-approval changes-refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery. The most effective way to avoid the timeline impact of design changes is to ensure that the design is truly final before production preparation begins-which requires thorough stakeholder engagement during the design phase, not after.

The supplier's perspective on design changes is fundamentally protective. Suppliers have learned from experience that design changes after approval are a leading cause of project delays, cost overruns, and client dissatisfaction. A supplier who proceeds with production based on a design that has not been fully approved by all stakeholders risks producing boxes that will be rejected-a costly outcome for both parties. A supplier who orders materials based on a design that is subsequently changed risks wasting those materials-another costly outcome. The supplier's insistence on re-proofing, re-approval, and material verification is not bureaucratic obstruction-it's risk management. The supplier is protecting both parties from the consequences of proceeding with production before the design is truly final. Procurement teams who understand this perspective can work more effectively with their suppliers, providing clear and complete design specifications upfront and minimising the need for post-approval changes.

The organisational discipline required to minimise design changes is often underestimated. In many organisations, design approval is treated as a formality-a box to be checked before production can begin. Stakeholders review designs quickly, provide superficial approval, and assume that any issues can be addressed later. This approach creates a culture where design changes are normalised, and the timeline impact of those changes is absorbed as an unavoidable cost of doing business. The alternative approach-treating design approval as a genuine decision point that requires thorough review and commitment-requires more effort upfront but saves significant time and cost downstream. Procurement teams should establish clear approval protocols that require stakeholders to confirm that they have reviewed the design thoroughly and that they will not request changes after approval except for essential corrections. This cultural shift-from "approval is a formality" to "approval is a commitment"-is the most effective way to reduce the timeline impact of design changes.

The version control chaos that accompanies design changes creates additional risk and delay. When multiple stakeholders are involved in the approval process, and multiple revision rounds occur, the risk of version confusion increases dramatically. The design team may be working on version 9, while the legal team has just reviewed version 8, marketing is referencing version 7 for promotional materials, and the supplier received version 6. This version misalignment causes duplicate work, conflicting feedback, and additional revision cycles. A procurement team may approve a design change, only to discover that the supplier implemented the change on an outdated version of the file. The change must be re-implemented on the correct version, triggering another proof cycle. These version control issues are not the result of incompetence-they are the predictable consequence of managing complex design projects across multiple stakeholders without centralised version management systems.

The cost implications of design changes extend beyond timeline delays. When a supplier has already ordered materials based on the original design, and a design change renders those materials incompatible, someone must absorb the cost of the wasted materials. If the supplier absorbs the cost, they may increase their pricing on future projects to account for the risk of design changes. If the buyer absorbs the cost, the project budget increases unexpectedly. When a supplier has already created printing plates, foil dies, or embossing dies based on the original design, and a design change requires new tooling, the cost of the original tooling is wasted. These costs are rarely visible in the initial project quotation, because the quotation assumes that the design will be finalised before production begins. When design changes occur after production preparation has started, the hidden costs emerge-and they can be substantial for complex projects with multiple finishing processes.

The practical reality is that design changes after approval should be treated as exceptions, not routine adjustments. When a procurement team is considering a design change, they should ask themselves: "Is this change essential, or is it a preference?" Essential changes-such as correcting a regulatory error or fixing a brand guideline violation-justify the timeline and cost impact. Preference changes-such as making a logo slightly larger because an executive thinks it looks better-may not justify the impact. The procurement team should also ask: "Can this change be incorporated into the next order, rather than this order?" If the change is not essential for the current project, deferring it to a future order avoids the timeline disruption and cost impact entirely.

When planning custom corporate gift box projects, it's essential to build in adequate time for design development and stakeholder alignment before production begins. For comprehensive guidance on structuring realistic timelines that minimise the need for post-approval changes-refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery. The most effective way to avoid the timeline impact of design changes is to ensure that the design is truly final before production preparation begins-which requires thorough stakeholder engagement during the design phase, not after.

The supplier's perspective on design changes is fundamentally protective. Suppliers have learned from experience that design changes after approval are a leading cause of project delays, cost overruns, and client dissatisfaction. A supplier who proceeds with production based on a design that has not been fully approved by all stakeholders risks producing boxes that will be rejected-a costly outcome for both parties. A supplier who orders materials based on a design that is subsequently changed risks wasting those materials-another costly outcome. The supplier's insistence on re-proofing, re-approval, and material verification is not bureaucratic obstruction-it's risk management. The supplier is protecting both parties from the consequences of proceeding with production before the design is truly final. Procurement teams who understand this perspective can work more effectively with their suppliers, providing clear and complete design specifications upfront and minimising the need for post-approval changes.

The organisational discipline required to minimise design changes is often underestimated. In many organisations, design approval is treated as a formality-a box to be checked before production can begin. Stakeholders review designs quickly, provide superficial approval, and assume that any issues can be addressed later. This approach creates a culture where design changes are normalised, and the timeline impact of those changes is absorbed as an unavoidable cost of doing business. The alternative approach-treating design approval as a genuine decision point that requires thorough review and commitment-requires more effort upfront but saves significant time and cost downstream. Procurement teams should establish clear approval protocols that require stakeholders to confirm that they have reviewed the design thoroughly and that they will not request changes after approval except for essential corrections. This cultural shift-from "approval is a formality" to "approval is a commitment"-is the most effective way to reduce the timeline impact of design changes.

The stakeholder re-approval requirement is often invisible to the procurement team requesting the change. When the original design was approved, it was approved by multiple stakeholders-procurement, marketing, compliance, and potentially an executive sponsor. Each of these stakeholders signed off on specific aspects of the design: marketing approved the brand consistency, compliance approved the regulatory text, and the executive sponsor approved the strategic messaging. When a design change is made-even a "minor" one-the supplier cannot assume that the previous approvals still apply. A logo resize might affect the visual balance that marketing approved. A colour tweak might affect the brand consistency that was previously confirmed. A text addition might affect the regulatory compliance that was previously verified. The supplier must obtain fresh approvals from all relevant stakeholders before proceeding, because proceeding without approval creates liability risk. If the production run is completed and a stakeholder later objects to the change, the supplier may be held responsible for producing boxes that were not properly approved.

The material compatibility verification is another source of timeline extension that procurement teams rarely anticipate. When a supplier prepares for production, they order materials based on the approved design specifications. Paper stock is ordered in quantities that match the production volume. Printing plates are created based on the approved artwork. Foil dies are manufactured based on the approved foil placement. Embossing dies are created based on the approved embossing design. When a design change is requested, the supplier must verify that the materials already ordered are still compatible with the revised design. A logo resize might require a new printing plate. A colour tweak might require different ink formulations. A text addition might require reflowing the layout, which could affect the paper stock requirements. If the materials on hand are not compatible with the revised design, the supplier must order new materials-a process that adds 1-2 weeks to the timeline, depending on material availability and supplier lead times.

The production queue repositioning is the most significant source of timeline extension, and it's the one that procurement teams understand least. Suppliers schedule their production capacity weeks in advance, allocating machine time, labour, and finishing capacity to specific projects. When a design change is requested, the supplier cannot simply pause the project and resume it later-they must release the allocated production slot and reschedule the project into a future slot. The original slot is then allocated to another project that is ready for production. When the revised design is finally approved and materials are verified, the supplier must find a new production slot-which may be 1-2 weeks later than the original slot, depending on the supplier's production schedule. The procurement team has not only lost time to the re-proofing and re-approval process-they have lost additional time to production queue repositioning. The cumulative timeline impact of a "minor change" can be 3-4 weeks: 1 week for re-proofing and re-approval, 1-2 weeks for material verification and potential re-ordering, and 1-2 weeks for production queue repositioning.

The stakeholder re-approval requirement is often invisible to the procurement team requesting the change. When the original design was approved, it was approved by multiple stakeholders-procurement, marketing, compliance, and potentially an executive sponsor. Each of these stakeholders signed off on specific aspects of the design: marketing approved the brand consistency, compliance approved the regulatory text, and the executive sponsor approved the strategic messaging. When a design change is made-even a "minor" one-the supplier cannot assume that the previous approvals still apply. A logo resize might affect the visual balance that marketing approved. A colour tweak might affect the brand consistency that was previously confirmed. A text addition might affect the regulatory compliance that was previously verified. The supplier must obtain fresh approvals from all relevant stakeholders before proceeding, because proceeding without approval creates liability risk. If the production run is completed and a stakeholder later objects to the change, the supplier may be held responsible for producing boxes that were not properly approved.

The material compatibility verification is another source of timeline extension that procurement teams rarely anticipate. When a supplier prepares for production, they order materials based on the approved design specifications. Paper stock is ordered in quantities that match the production volume. Printing plates are created based on the approved artwork. Foil dies are manufactured based on the approved foil placement. Embossing dies are created based on the approved embossing design. When a design change is requested, the supplier must verify that the materials already ordered are still compatible with the revised design. A logo resize might require a new printing plate. A colour tweak might require different ink formulations. A text addition might require reflowing the layout, which could affect the paper stock requirements. If the materials on hand are not compatible with the revised design, the supplier must order new materials-a process that adds 1-2 weeks to the timeline, depending on material availability and supplier lead times.

The production queue repositioning is the most significant source of timeline extension, and it's the one that procurement teams understand least. Suppliers schedule their production capacity weeks in advance, allocating machine time, labour, and finishing capacity to specific projects. When a design change is requested, the supplier cannot simply pause the project and resume it later-they must release the allocated production slot and reschedule the project into a future slot. The original slot is then allocated to another project that is ready for production. When the revised design is finally approved and materials are verified, the supplier must find a new production slot-which may be 1-2 weeks later than the original slot, depending on the supplier's production schedule. The procurement team has not only lost time to the re-proofing and re-approval process-they have lost additional time to production queue repositioning. The cumulative timeline impact of a "minor change" can be 3-4 weeks: 1 week for re-proofing and re-approval, 1-2 weeks for material verification and potential re-ordering, and 1-2 weeks for production queue repositioning.

The version control chaos that accompanies design changes creates additional risk and delay. When multiple stakeholders are involved in the approval process, and multiple revision rounds occur, the risk of version confusion increases dramatically. The design team may be working on version 9, while the legal team has just reviewed version 8, marketing is referencing version 7 for promotional materials, and the supplier received version 6. This version misalignment causes duplicate work, conflicting feedback, and additional revision cycles. A procurement team may approve a design change, only to discover that the supplier implemented the change on an outdated version of the file. The change must be re-implemented on the correct version, triggering another proof cycle. These version control issues are not the result of incompetence-they are the predictable consequence of managing complex design projects across multiple stakeholders without centralised version management systems.

The cost implications of design changes extend beyond timeline delays. When a supplier has already ordered materials based on the original design, and a design change renders those materials incompatible, someone must absorb the cost of the wasted materials. If the supplier absorbs the cost, they may increase their pricing on future projects to account for the risk of design changes. If the buyer absorbs the cost, the project budget increases unexpectedly. When a supplier has already created printing plates, foil dies, or embossing dies based on the original design, and a design change requires new tooling, the cost of the original tooling is wasted. These costs are rarely visible in the initial project quotation, because the quotation assumes that the design will be finalised before production begins. When design changes occur after production preparation has started, the hidden costs emerge-and they can be substantial for complex projects with multiple finishing processes.

The practical reality is that design changes after approval should be treated as exceptions, not routine adjustments. When a procurement team is considering a design change, they should ask themselves: "Is this change essential, or is it a preference?" Essential changes-such as correcting a regulatory error or fixing a brand guideline violation-justify the timeline and cost impact. Preference changes-such as making a logo slightly larger because an executive thinks it looks better-may not justify the impact. The procurement team should also ask: "Can this change be incorporated into the next order, rather than this order?" If the change is not essential for the current project, deferring it to a future order avoids the timeline disruption and cost impact entirely.

When planning custom corporate gift box projects, it's essential to build in adequate time for design development and stakeholder alignment before production begins. For comprehensive guidance on structuring realistic timelines that minimise the need for post-approval changes-refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery. The most effective way to avoid the timeline impact of design changes is to ensure that the design is truly final before production preparation begins-which requires thorough stakeholder engagement during the design phase, not after.

The supplier's perspective on design changes is fundamentally protective. Suppliers have learned from experience that design changes after approval are a leading cause of project delays, cost overruns, and client dissatisfaction. A supplier who proceeds with production based on a design that has not been fully approved by all stakeholders risks producing boxes that will be rejected-a costly outcome for both parties. A supplier who orders materials based on a design that is subsequently changed risks wasting those materials-another costly outcome. The supplier's insistence on re-proofing, re-approval, and material verification is not bureaucratic obstruction-it's risk management. The supplier is protecting both parties from the consequences of proceeding with production before the design is truly final. Procurement teams who understand this perspective can work more effectively with their suppliers, providing clear and complete design specifications upfront and minimising the need for post-approval changes.

The organisational discipline required to minimise design changes is often underestimated. In many organisations, design approval is treated as a formality-a box to be checked before production can begin. Stakeholders review designs quickly, provide superficial approval, and assume that any issues can be addressed later. This approach creates a culture where design changes are normalised, and the timeline impact of those changes is absorbed as an unavoidable cost of doing business. The alternative approach-treating design approval as a genuine decision point that requires thorough review and commitment-requires more effort upfront but saves significant time and cost downstream. Procurement teams should establish clear approval protocols that require stakeholders to confirm that they have reviewed the design thoroughly and that they will not request changes after approval except for essential corrections. This cultural shift-from "approval is a formality" to "approval is a commitment"-is the most effective way to reduce the timeline impact of design changes.

The version control chaos that accompanies design changes creates additional risk and delay. When multiple stakeholders are involved in the approval process, and multiple revision rounds occur, the risk of version confusion increases dramatically. The design team may be working on version 9, while the legal team has just reviewed version 8, marketing is referencing version 7 for promotional materials, and the supplier received version 6. This version misalignment causes duplicate work, conflicting feedback, and additional revision cycles. A procurement team may approve a design change, only to discover that the supplier implemented the change on an outdated version of the file. The change must be re-implemented on the correct version, triggering another proof cycle. These version control issues are not the result of incompetence-they are the predictable consequence of managing complex design projects across multiple stakeholders without centralised version management systems.

The cost implications of design changes extend beyond timeline delays. When a supplier has already ordered materials based on the original design, and a design change renders those materials incompatible, someone must absorb the cost of the wasted materials. If the supplier absorbs the cost, they may increase their pricing on future projects to account for the risk of design changes. If the buyer absorbs the cost, the project budget increases unexpectedly. When a supplier has already created printing plates, foil dies, or embossing dies based on the original design, and a design change requires new tooling, the cost of the original tooling is wasted. These costs are rarely visible in the initial project quotation, because the quotation assumes that the design will be finalised before production begins. When design changes occur after production preparation has started, the hidden costs emerge-and they can be substantial for complex projects with multiple finishing processes.

The practical reality is that design changes after approval should be treated as exceptions, not routine adjustments. When a procurement team is considering a design change, they should ask themselves: "Is this change essential, or is it a preference?" Essential changes-such as correcting a regulatory error or fixing a brand guideline violation-justify the timeline and cost impact. Preference changes-such as making a logo slightly larger because an executive thinks it looks better-may not justify the impact. The procurement team should also ask: "Can this change be incorporated into the next order, rather than this order?" If the change is not essential for the current project, deferring it to a future order avoids the timeline disruption and cost impact entirely.

When planning custom corporate gift box projects, it's essential to build in adequate time for design development and stakeholder alignment before production begins. For comprehensive guidance on structuring realistic timelines that minimise the need for post-approval changes-refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery. The most effective way to avoid the timeline impact of design changes is to ensure that the design is truly final before production preparation begins-which requires thorough stakeholder engagement during the design phase, not after.

The supplier's perspective on design changes is fundamentally protective. Suppliers have learned from experience that design changes after approval are a leading cause of project delays, cost overruns, and client dissatisfaction. A supplier who proceeds with production based on a design that has not been fully approved by all stakeholders risks producing boxes that will be rejected-a costly outcome for both parties. A supplier who orders materials based on a design that is subsequently changed risks wasting those materials-another costly outcome. The supplier's insistence on re-proofing, re-approval, and material verification is not bureaucratic obstruction-it's risk management. The supplier is protecting both parties from the consequences of proceeding with production before the design is truly final. Procurement teams who understand this perspective can work more effectively with their suppliers, providing clear and complete design specifications upfront and minimising the need for post-approval changes.

The organisational discipline required to minimise design changes is often underestimated. In many organisations, design approval is treated as a formality-a box to be checked before production can begin. Stakeholders review designs quickly, provide superficial approval, and assume that any issues can be addressed later. This approach creates a culture where design changes are normalised, and the timeline impact of those changes is absorbed as an unavoidable cost of doing business. The alternative approach-treating design approval as a genuine decision point that requires thorough review and commitment-requires more effort upfront but saves significant time and cost downstream. Procurement teams should establish clear approval protocols that require stakeholders to confirm that they have reviewed the design thoroughly and that they will not request changes after approval except for essential corrections. This cultural shift-from "approval is a formality" to "approval is a commitment"-is the most effective way to reduce the timeline impact of design changes.

You May Also Like

Rigid Box vs. Corrugated Mailer: Which Material Suits Your Premium Corporate Gifts?

A deep dive into the structural integrity, cost implications, and unboxing experience of rigid boxes versus corrugated mailers for high-end corporate gifting.

Foil Stamping vs. UV Spot: Elevating Your Brand Logo on Custom Gift Boxes

A technical comparison of hot foil stamping and UV spot varnish, analyzing visual impact, durability, and production costs for branded corporate packaging.