Back to BlogCustomization Process

Why Adding Foil Stamping + Embossing to Your Corporate Gift Box Doesn't Add 3 Days—It Adds 3 Weeks

2026-01-31

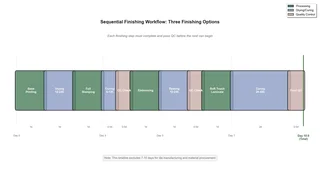

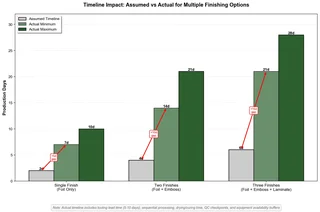

When procurement teams specify multiple finishing options for custom corporate gift boxes—foil stamping for the logo, embossing for the brand name, soft touch laminate for the texture—they typically assume each finishing option adds 1-2 days to the production timeline. Three finishing options should add 3-6 days. In practice, the relationship between number of finishing options and total lead time is non-linear, because each finishing technique requires sequential processing, separate tooling, dedicated drying time, and independent quality control checkpoints. The actual timeline impact of three finishing options is 2-3 weeks, not 3-6 days. This misjudgment occurs because procurement teams focus on the "per-unit processing time" for each finishing technique—how long it takes to foil stamp one box, how long it takes to emboss one box—without accounting for the setup time, tooling lead time, drying time, and quality control time that each finishing technique introduces. These fixed time components do not scale with volume, and they cannot be parallelized. The result is a systematic underestimation of total project duration by 2-4 weeks, depending on the number and complexity of finishing options specified.

The misjudgment begins with how finishing options are presented in supplier quotations and procurement specifications. When a procurement team requests a quote for custom corporate gift boxes with foil stamping, embossing, and soft touch laminate, the supplier provides a per-unit price for each finishing option. The quote might show: base box £2.50, foil stamping +£0.40, embossing +£0.35, soft touch laminate +£0.25. The total per-unit cost is £3.50. The procurement team sees these incremental costs and assumes that the timeline impact is similarly incremental—if foil stamping adds £0.40 to the unit cost, it should add 1-2 days to the timeline. If embossing adds £0.35, it should add another 1-2 days. The total timeline impact should be 3-6 days. This assumption is incorrect because it conflates variable costs (which scale with volume) with fixed time components (which do not scale with volume). The per-unit price for foil stamping includes the amortized cost of die creation, machine setup, and operator time. The timeline impact, however, is dominated by the fixed time components—die manufacturing lead time (5-7 days), machine setup time (4-6 hours), drying time (12-24 hours), and quality control inspection time (2-3 days). These fixed time components must be completed for each finishing technique, and they cannot be parallelized because each finishing technique must be applied sequentially.

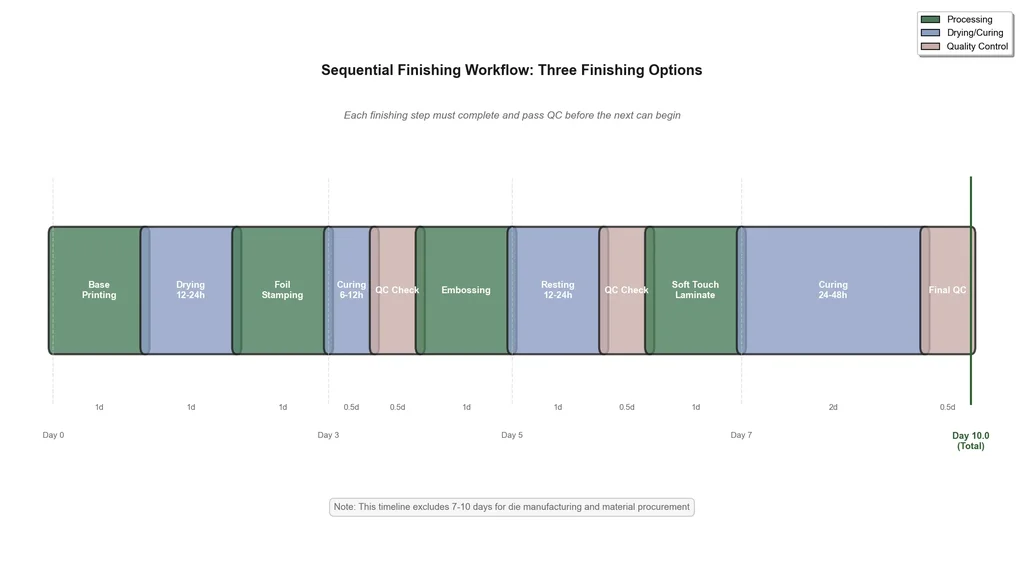

The sequential processing requirement is the primary driver of timeline multiplication. Foil stamping cannot be applied until the base printing is complete and fully dried. Embossing cannot be applied until the foil stamping is complete and fully dried. Soft touch laminate cannot be applied until the embossing is complete and the surface is clean and stable. Each finishing technique requires a stable substrate—meaning the previous layer must be fully cured, inspected, and approved before the next layer can be applied. If foil stamping is applied to a substrate that is not fully dried, the heat and pressure from the foil stamping process will cause the ink to smudge or the substrate to warp. If embossing is applied to a substrate that still has residual moisture from the foil stamping adhesive, the embossing die will not create a clean impression. If soft touch laminate is applied to a substrate that has surface contamination from the embossing process, the laminate will not adhere properly and will peel off during handling. These are not theoretical risks—they are common quality failures that occur when finishing techniques are rushed or applied out of sequence. Suppliers know from experience that each finishing technique must be fully completed and quality-checked before the next technique can begin. This is why the timeline impact is sequential, not parallel.

The tooling lead time for each finishing technique is often invisible to procurement teams because it is not explicitly stated in the production timeline. When a procurement team approves a design and expects production to begin immediately, they assume that the supplier has all the necessary tools and equipment ready to go. In reality, each finishing technique requires custom tooling that must be manufactured specifically for the project. Foil stamping requires a metal die that is engraved with the logo or text to be stamped. This die must be manufactured by a specialist die-maker, which takes 5-7 business days from the time the design is finalized. Embossing requires both a male die (the raised portion) and a female die (the recessed portion) that must be precisely matched to create the embossed effect. These dies are typically made from magnesium or brass, and they take 7-10 business days to manufacture. Soft touch laminate does not require custom tooling, but it does require the supplier to order the laminate material from a specialty supplier, which can take 3-5 business days if the material is not in stock. The cumulative tooling lead time for three finishing options is 7-10 days, assuming the dies and materials are ordered simultaneously. If the dies and materials are ordered sequentially—because the design is not finalized until after the first die is ordered—the cumulative tooling lead time can be 2-3 weeks.

The drying and curing time for each finishing technique is another fixed time component that cannot be compressed. After the base printing is complete, the ink must dry for 12-24 hours before foil stamping can be applied. This drying time is necessary to ensure that the ink has fully cured and will not smudge or transfer during the foil stamping process. After foil stamping is complete, the foil adhesive must cure for 6-12 hours before embossing can be applied. This curing time is necessary to ensure that the foil has fully bonded to the substrate and will not peel off during the embossing process. After embossing is complete, the substrate must rest for 12-24 hours to allow any residual moisture to evaporate and the embossed impression to stabilize. After soft touch laminate is applied, the laminate adhesive must cure for 24-48 hours before the boxes can be die-cut, folded, and packed. The cumulative drying and curing time for three finishing options is 54-108 hours (2.25-4.5 days), assuming each layer is applied immediately after the previous layer has dried. In practice, the cumulative drying time is longer because production schedules do not allow for immediate sequential processing—there are gaps between each finishing step while the substrate is moved between machines, inspected, and queued for the next process.

The quality control checkpoints between each finishing step introduce additional time that is rarely accounted for in procurement timelines. After the base printing is complete, the supplier must inspect a sample of the printed sheets to verify color accuracy, registration, and print quality. This inspection takes 2-4 hours, and if any quality issues are identified, the entire print run must be reprinted. After foil stamping is complete, the supplier must inspect a sample of the foil-stamped sheets to verify foil adhesion, registration accuracy, and visual consistency. This inspection takes 2-4 hours, and if any quality issues are identified, the foil stamping process must be repeated. After embossing is complete, the supplier must inspect a sample of the embossed sheets to verify impression depth, registration accuracy, and surface cleanliness. This inspection takes 2-4 hours, and if any quality issues are identified, the embossing process must be repeated. After soft touch laminate is applied, the supplier must inspect a sample of the laminated sheets to verify adhesion, surface smoothness, and absence of bubbles or wrinkles. This inspection takes 2-4 hours, and if any quality issues are identified, the lamination process must be repeated. The cumulative quality control time for three finishing options is 8-16 hours (1-2 days), assuming no quality issues are identified. If quality issues are identified at any stage, the cumulative quality control time can be 3-5 days, because each rework cycle requires re-inspection and re-approval.

The tooling lead time for each finishing technique is often invisible to procurement teams because it is not explicitly stated in the production timeline. When a procurement team approves a design and expects production to begin immediately, they assume that the supplier has all the necessary tools and equipment ready to go. In reality, each finishing technique requires custom tooling that must be manufactured specifically for the project. Foil stamping requires a metal die that is engraved with the logo or text to be stamped. This die must be manufactured by a specialist die-maker, which takes 5-7 business days from the time the design is finalized. Embossing requires both a male die (the raised portion) and a female die (the recessed portion) that must be precisely matched to create the embossed effect. These dies are typically made from magnesium or brass, and they take 7-10 business days to manufacture. Soft touch laminate does not require custom tooling, but it does require the supplier to order the laminate material from a specialty supplier, which can take 3-5 business days if the material is not in stock. The cumulative tooling lead time for three finishing options is 7-10 days, assuming the dies and materials are ordered simultaneously. If the dies and materials are ordered sequentially—because the design is not finalized until after the first die is ordered—the cumulative tooling lead time can be 2-3 weeks.

The drying and curing time for each finishing technique is another fixed time component that cannot be compressed. After the base printing is complete, the ink must dry for 12-24 hours before foil stamping can be applied. This drying time is necessary to ensure that the ink has fully cured and will not smudge or transfer during the foil stamping process. After foil stamping is complete, the foil adhesive must cure for 6-12 hours before embossing can be applied. This curing time is necessary to ensure that the foil has fully bonded to the substrate and will not peel off during the embossing process. After embossing is complete, the substrate must rest for 12-24 hours to allow any residual moisture to evaporate and the embossed impression to stabilize. After soft touch laminate is applied, the laminate adhesive must cure for 24-48 hours before the boxes can be die-cut, folded, and packed. The cumulative drying and curing time for three finishing options is 54-108 hours (2.25-4.5 days), assuming each layer is applied immediately after the previous layer has dried. In practice, the cumulative drying time is longer because production schedules do not allow for immediate sequential processing—there are gaps between each finishing step while the substrate is moved between machines, inspected, and queued for the next process.

The quality control checkpoints between each finishing step introduce additional time that is rarely accounted for in procurement timelines. After the base printing is complete, the supplier must inspect a sample of the printed sheets to verify color accuracy, registration, and print quality. This inspection takes 2-4 hours, and if any quality issues are identified, the entire print run must be reprinted. After foil stamping is complete, the supplier must inspect a sample of the foil-stamped sheets to verify foil adhesion, registration accuracy, and visual consistency. This inspection takes 2-4 hours, and if any quality issues are identified, the foil stamping process must be repeated. After embossing is complete, the supplier must inspect a sample of the embossed sheets to verify impression depth, registration accuracy, and surface cleanliness. This inspection takes 2-4 hours, and if any quality issues are identified, the embossing process must be repeated. After soft touch laminate is applied, the supplier must inspect a sample of the laminated sheets to verify adhesion, surface smoothness, and absence of bubbles or wrinkles. This inspection takes 2-4 hours, and if any quality issues are identified, the lamination process must be repeated. The cumulative quality control time for three finishing options is 8-16 hours (1-2 days), assuming no quality issues are identified. If quality issues are identified at any stage, the cumulative quality control time can be 3-5 days, because each rework cycle requires re-inspection and re-approval.

The equipment availability constraint is another factor that multiplies timeline impact. Not all finishing equipment is available in-house at every packaging supplier. Foil stamping and embossing require specialized presses that are expensive to purchase and maintain, so many packaging suppliers outsource these processes to specialist finishing houses. When a supplier outsources a finishing process, they must coordinate with the finishing house's production schedule, which adds 3-5 days to the timeline for each finishing process that is outsourced. If foil stamping and embossing are both outsourced, the cumulative timeline impact is 6-10 days, not including the transportation time to and from the finishing house. Soft touch laminate is typically applied in-house, but the laminating equipment has limited capacity and must be scheduled in advance. If the laminating equipment is fully booked when the embossed sheets are ready, the supplier must wait 2-3 days for an available slot. The cumulative equipment availability delay for three finishing options can be 8-13 days, depending on the supplier's in-house capabilities and the external finishing house's production schedule.

The rejection and rework risk increases significantly with each additional finishing option. A single-layer print job has a rejection rate of 2-5%, meaning that 2-5% of the printed sheets will be rejected due to quality issues and must be reprinted. A two-layer finishing job (print + foil stamping) has a rejection rate of 5-10%, because quality issues can occur at either the printing stage or the foil stamping stage. A three-layer finishing job (print + foil stamping + embossing) has a rejection rate of 10-15%, because quality issues can occur at any of the three stages. A four-layer finishing job (print + foil stamping + embossing + laminate) has a rejection rate of 15-20%. Each rejected sheet must be reprinted, re-foil stamped, re-embossed, and re-laminated, which adds 3-7 days to the timeline for each rework cycle. The probability of at least one rework cycle increases with the number of finishing options. For a single-layer print job, the probability of rework is 2-5%. For a four-layer finishing job, the probability of rework is 50-70%. The expected timeline impact of rework for a four-layer finishing job is 2-5 days, which must be added to the base timeline to calculate the realistic delivery date.

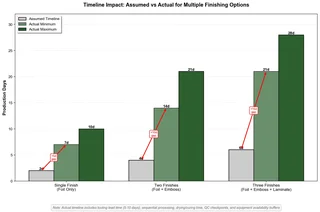

The compounding effect of these fixed time components is what causes the non-linear relationship between number of finishing options and total lead time. A single finishing option (foil stamping only) adds 7-10 days to the base production timeline: 5-7 days for die manufacturing, 1 day for machine setup and processing, 1 day for drying, 0.5 days for quality control. Two finishing options (foil stamping + embossing) add 14-21 days to the base production timeline: 7-10 days for die manufacturing (both dies ordered simultaneously), 2 days for sequential processing, 2 days for drying, 1 day for quality control, 2-6 days for equipment availability delays. Three finishing options (foil stamping + embossing + soft touch laminate) add 21-28 days to the base production timeline: 7-10 days for tooling and material procurement, 3 days for sequential processing, 3 days for drying, 1.5 days for quality control, 4-8 days for equipment availability delays, 2-5 days for expected rework. The timeline impact is not linear (7 days, 14 days, 21 days)—it is multiplicative (7 days, 14-21 days, 21-28 days) because the fixed time components compound at each stage.

When evaluating finishing options for custom corporate gift projects, it's essential to understand how sequential processing requirements, tooling lead times, and quality control checkpoints interact to create non-linear timeline impacts. For comprehensive guidance on structuring realistic timelines that accommodate the full complexity of multi-layer finishing processes, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to specify finishing options early in the design process and confirm tooling lead times before finalizing the project timeline. Instead of adding finishing options as an afterthought—"Can we add foil stamping to the logo?"—procurement teams should specify all desired finishing options in the initial design brief and request a detailed timeline breakdown from the supplier. The supplier should provide a timeline that explicitly shows: die manufacturing lead time (5-7 days), material procurement lead time (3-5 days), sequential processing time (3 days), drying and curing time (3 days), quality control time (1.5 days), equipment availability buffer (4-8 days), and expected rework buffer (2-5 days). The total timeline for three finishing options is 21-28 days, not 3-6 days. By understanding the true timeline impact of finishing options and planning accordingly, procurement teams can avoid the costly surprises that arise when "add foil stamping and embossing" is interpreted as "add 3 days to the timeline" instead of "add 3 weeks to the timeline."

The supplier's perspective on finishing complexity is fundamentally different from the buyer's perspective. For buyers, finishing options are aesthetic enhancements that make the product more premium and visually appealing. For suppliers, finishing options are sequential manufacturing processes that introduce tooling dependencies, drying time constraints, quality control checkpoints, and rework risks. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that finishing options add incrementally to the timeline, while suppliers know that finishing options multiply the timeline due to sequential dependencies. The gap between these assumptions is 2-3 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for the fixed time components of each finishing option, procurement teams can bridge this gap and plan realistic timelines that account for the full complexity of multi-layer finishing processes.

The equipment availability constraint is another factor that multiplies timeline impact. Not all finishing equipment is available in-house at every packaging supplier. Foil stamping and embossing require specialized presses that are expensive to purchase and maintain, so many packaging suppliers outsource these processes to specialist finishing houses. When a supplier outsources a finishing process, they must coordinate with the finishing house's production schedule, which adds 3-5 days to the timeline for each finishing process that is outsourced. If foil stamping and embossing are both outsourced, the cumulative timeline impact is 6-10 days, not including the transportation time to and from the finishing house. Soft touch laminate is typically applied in-house, but the laminating equipment has limited capacity and must be scheduled in advance. If the laminating equipment is fully booked when the embossed sheets are ready, the supplier must wait 2-3 days for an available slot. The cumulative equipment availability delay for three finishing options can be 8-13 days, depending on the supplier's in-house capabilities and the external finishing house's production schedule.

The rejection and rework risk increases significantly with each additional finishing option. A single-layer print job has a rejection rate of 2-5%, meaning that 2-5% of the printed sheets will be rejected due to quality issues and must be reprinted. A two-layer finishing job (print + foil stamping) has a rejection rate of 5-10%, because quality issues can occur at either the printing stage or the foil stamping stage. A three-layer finishing job (print + foil stamping + embossing) has a rejection rate of 10-15%, because quality issues can occur at any of the three stages. A four-layer finishing job (print + foil stamping + embossing + laminate) has a rejection rate of 15-20%. Each rejected sheet must be reprinted, re-foil stamped, re-embossed, and re-laminated, which adds 3-7 days to the timeline for each rework cycle. The probability of at least one rework cycle increases with the number of finishing options. For a single-layer print job, the probability of rework is 2-5%. For a four-layer finishing job, the probability of rework is 50-70%. The expected timeline impact of rework for a four-layer finishing job is 2-5 days, which must be added to the base timeline to calculate the realistic delivery date.

The compounding effect of these fixed time components is what causes the non-linear relationship between number of finishing options and total lead time. A single finishing option (foil stamping only) adds 7-10 days to the base production timeline: 5-7 days for die manufacturing, 1 day for machine setup and processing, 1 day for drying, 0.5 days for quality control. Two finishing options (foil stamping + embossing) add 14-21 days to the base production timeline: 7-10 days for die manufacturing (both dies ordered simultaneously), 2 days for sequential processing, 2 days for drying, 1 day for quality control, 2-6 days for equipment availability delays. Three finishing options (foil stamping + embossing + soft touch laminate) add 21-28 days to the base production timeline: 7-10 days for tooling and material procurement, 3 days for sequential processing, 3 days for drying, 1.5 days for quality control, 4-8 days for equipment availability delays, 2-5 days for expected rework. The timeline impact is not linear (7 days, 14 days, 21 days)—it is multiplicative (7 days, 14-21 days, 21-28 days) because the fixed time components compound at each stage.

When evaluating finishing options for custom corporate gift projects, it's essential to understand how sequential processing requirements, tooling lead times, and quality control checkpoints interact to create non-linear timeline impacts. For comprehensive guidance on structuring realistic timelines that accommodate the full complexity of multi-layer finishing processes, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to specify finishing options early in the design process and confirm tooling lead times before finalizing the project timeline. Instead of adding finishing options as an afterthought—"Can we add foil stamping to the logo?"—procurement teams should specify all desired finishing options in the initial design brief and request a detailed timeline breakdown from the supplier. The supplier should provide a timeline that explicitly shows: die manufacturing lead time (5-7 days), material procurement lead time (3-5 days), sequential processing time (3 days), drying and curing time (3 days), quality control time (1.5 days), equipment availability buffer (4-8 days), and expected rework buffer (2-5 days). The total timeline for three finishing options is 21-28 days, not 3-6 days. By understanding the true timeline impact of finishing options and planning accordingly, procurement teams can avoid the costly surprises that arise when "add foil stamping and embossing" is interpreted as "add 3 days to the timeline" instead of "add 3 weeks to the timeline."

The supplier's perspective on finishing complexity is fundamentally different from the buyer's perspective. For buyers, finishing options are aesthetic enhancements that make the product more premium and visually appealing. For suppliers, finishing options are sequential manufacturing processes that introduce tooling dependencies, drying time constraints, quality control checkpoints, and rework risks. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that finishing options add incrementally to the timeline, while suppliers know that finishing options multiply the timeline due to sequential dependencies. The gap between these assumptions is 2-3 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for the fixed time components of each finishing option, procurement teams can bridge this gap and plan realistic timelines that account for the full complexity of multi-layer finishing processes.

The tooling lead time for each finishing technique is often invisible to procurement teams because it is not explicitly stated in the production timeline. When a procurement team approves a design and expects production to begin immediately, they assume that the supplier has all the necessary tools and equipment ready to go. In reality, each finishing technique requires custom tooling that must be manufactured specifically for the project. Foil stamping requires a metal die that is engraved with the logo or text to be stamped. This die must be manufactured by a specialist die-maker, which takes 5-7 business days from the time the design is finalized. Embossing requires both a male die (the raised portion) and a female die (the recessed portion) that must be precisely matched to create the embossed effect. These dies are typically made from magnesium or brass, and they take 7-10 business days to manufacture. Soft touch laminate does not require custom tooling, but it does require the supplier to order the laminate material from a specialty supplier, which can take 3-5 business days if the material is not in stock. The cumulative tooling lead time for three finishing options is 7-10 days, assuming the dies and materials are ordered simultaneously. If the dies and materials are ordered sequentially—because the design is not finalized until after the first die is ordered—the cumulative tooling lead time can be 2-3 weeks.

The drying and curing time for each finishing technique is another fixed time component that cannot be compressed. After the base printing is complete, the ink must dry for 12-24 hours before foil stamping can be applied. This drying time is necessary to ensure that the ink has fully cured and will not smudge or transfer during the foil stamping process. After foil stamping is complete, the foil adhesive must cure for 6-12 hours before embossing can be applied. This curing time is necessary to ensure that the foil has fully bonded to the substrate and will not peel off during the embossing process. After embossing is complete, the substrate must rest for 12-24 hours to allow any residual moisture to evaporate and the embossed impression to stabilize. After soft touch laminate is applied, the laminate adhesive must cure for 24-48 hours before the boxes can be die-cut, folded, and packed. The cumulative drying and curing time for three finishing options is 54-108 hours (2.25-4.5 days), assuming each layer is applied immediately after the previous layer has dried. In practice, the cumulative drying time is longer because production schedules do not allow for immediate sequential processing—there are gaps between each finishing step while the substrate is moved between machines, inspected, and queued for the next process.

The quality control checkpoints between each finishing step introduce additional time that is rarely accounted for in procurement timelines. After the base printing is complete, the supplier must inspect a sample of the printed sheets to verify color accuracy, registration, and print quality. This inspection takes 2-4 hours, and if any quality issues are identified, the entire print run must be reprinted. After foil stamping is complete, the supplier must inspect a sample of the foil-stamped sheets to verify foil adhesion, registration accuracy, and visual consistency. This inspection takes 2-4 hours, and if any quality issues are identified, the foil stamping process must be repeated. After embossing is complete, the supplier must inspect a sample of the embossed sheets to verify impression depth, registration accuracy, and surface cleanliness. This inspection takes 2-4 hours, and if any quality issues are identified, the embossing process must be repeated. After soft touch laminate is applied, the supplier must inspect a sample of the laminated sheets to verify adhesion, surface smoothness, and absence of bubbles or wrinkles. This inspection takes 2-4 hours, and if any quality issues are identified, the lamination process must be repeated. The cumulative quality control time for three finishing options is 8-16 hours (1-2 days), assuming no quality issues are identified. If quality issues are identified at any stage, the cumulative quality control time can be 3-5 days, because each rework cycle requires re-inspection and re-approval.

The tooling lead time for each finishing technique is often invisible to procurement teams because it is not explicitly stated in the production timeline. When a procurement team approves a design and expects production to begin immediately, they assume that the supplier has all the necessary tools and equipment ready to go. In reality, each finishing technique requires custom tooling that must be manufactured specifically for the project. Foil stamping requires a metal die that is engraved with the logo or text to be stamped. This die must be manufactured by a specialist die-maker, which takes 5-7 business days from the time the design is finalized. Embossing requires both a male die (the raised portion) and a female die (the recessed portion) that must be precisely matched to create the embossed effect. These dies are typically made from magnesium or brass, and they take 7-10 business days to manufacture. Soft touch laminate does not require custom tooling, but it does require the supplier to order the laminate material from a specialty supplier, which can take 3-5 business days if the material is not in stock. The cumulative tooling lead time for three finishing options is 7-10 days, assuming the dies and materials are ordered simultaneously. If the dies and materials are ordered sequentially—because the design is not finalized until after the first die is ordered—the cumulative tooling lead time can be 2-3 weeks.

The drying and curing time for each finishing technique is another fixed time component that cannot be compressed. After the base printing is complete, the ink must dry for 12-24 hours before foil stamping can be applied. This drying time is necessary to ensure that the ink has fully cured and will not smudge or transfer during the foil stamping process. After foil stamping is complete, the foil adhesive must cure for 6-12 hours before embossing can be applied. This curing time is necessary to ensure that the foil has fully bonded to the substrate and will not peel off during the embossing process. After embossing is complete, the substrate must rest for 12-24 hours to allow any residual moisture to evaporate and the embossed impression to stabilize. After soft touch laminate is applied, the laminate adhesive must cure for 24-48 hours before the boxes can be die-cut, folded, and packed. The cumulative drying and curing time for three finishing options is 54-108 hours (2.25-4.5 days), assuming each layer is applied immediately after the previous layer has dried. In practice, the cumulative drying time is longer because production schedules do not allow for immediate sequential processing—there are gaps between each finishing step while the substrate is moved between machines, inspected, and queued for the next process.

The quality control checkpoints between each finishing step introduce additional time that is rarely accounted for in procurement timelines. After the base printing is complete, the supplier must inspect a sample of the printed sheets to verify color accuracy, registration, and print quality. This inspection takes 2-4 hours, and if any quality issues are identified, the entire print run must be reprinted. After foil stamping is complete, the supplier must inspect a sample of the foil-stamped sheets to verify foil adhesion, registration accuracy, and visual consistency. This inspection takes 2-4 hours, and if any quality issues are identified, the foil stamping process must be repeated. After embossing is complete, the supplier must inspect a sample of the embossed sheets to verify impression depth, registration accuracy, and surface cleanliness. This inspection takes 2-4 hours, and if any quality issues are identified, the embossing process must be repeated. After soft touch laminate is applied, the supplier must inspect a sample of the laminated sheets to verify adhesion, surface smoothness, and absence of bubbles or wrinkles. This inspection takes 2-4 hours, and if any quality issues are identified, the lamination process must be repeated. The cumulative quality control time for three finishing options is 8-16 hours (1-2 days), assuming no quality issues are identified. If quality issues are identified at any stage, the cumulative quality control time can be 3-5 days, because each rework cycle requires re-inspection and re-approval.

The equipment availability constraint is another factor that multiplies timeline impact. Not all finishing equipment is available in-house at every packaging supplier. Foil stamping and embossing require specialized presses that are expensive to purchase and maintain, so many packaging suppliers outsource these processes to specialist finishing houses. When a supplier outsources a finishing process, they must coordinate with the finishing house's production schedule, which adds 3-5 days to the timeline for each finishing process that is outsourced. If foil stamping and embossing are both outsourced, the cumulative timeline impact is 6-10 days, not including the transportation time to and from the finishing house. Soft touch laminate is typically applied in-house, but the laminating equipment has limited capacity and must be scheduled in advance. If the laminating equipment is fully booked when the embossed sheets are ready, the supplier must wait 2-3 days for an available slot. The cumulative equipment availability delay for three finishing options can be 8-13 days, depending on the supplier's in-house capabilities and the external finishing house's production schedule.

The rejection and rework risk increases significantly with each additional finishing option. A single-layer print job has a rejection rate of 2-5%, meaning that 2-5% of the printed sheets will be rejected due to quality issues and must be reprinted. A two-layer finishing job (print + foil stamping) has a rejection rate of 5-10%, because quality issues can occur at either the printing stage or the foil stamping stage. A three-layer finishing job (print + foil stamping + embossing) has a rejection rate of 10-15%, because quality issues can occur at any of the three stages. A four-layer finishing job (print + foil stamping + embossing + laminate) has a rejection rate of 15-20%. Each rejected sheet must be reprinted, re-foil stamped, re-embossed, and re-laminated, which adds 3-7 days to the timeline for each rework cycle. The probability of at least one rework cycle increases with the number of finishing options. For a single-layer print job, the probability of rework is 2-5%. For a four-layer finishing job, the probability of rework is 50-70%. The expected timeline impact of rework for a four-layer finishing job is 2-5 days, which must be added to the base timeline to calculate the realistic delivery date.

The compounding effect of these fixed time components is what causes the non-linear relationship between number of finishing options and total lead time. A single finishing option (foil stamping only) adds 7-10 days to the base production timeline: 5-7 days for die manufacturing, 1 day for machine setup and processing, 1 day for drying, 0.5 days for quality control. Two finishing options (foil stamping + embossing) add 14-21 days to the base production timeline: 7-10 days for die manufacturing (both dies ordered simultaneously), 2 days for sequential processing, 2 days for drying, 1 day for quality control, 2-6 days for equipment availability delays. Three finishing options (foil stamping + embossing + soft touch laminate) add 21-28 days to the base production timeline: 7-10 days for tooling and material procurement, 3 days for sequential processing, 3 days for drying, 1.5 days for quality control, 4-8 days for equipment availability delays, 2-5 days for expected rework. The timeline impact is not linear (7 days, 14 days, 21 days)—it is multiplicative (7 days, 14-21 days, 21-28 days) because the fixed time components compound at each stage.

When evaluating finishing options for custom corporate gift projects, it's essential to understand how sequential processing requirements, tooling lead times, and quality control checkpoints interact to create non-linear timeline impacts. For comprehensive guidance on structuring realistic timelines that accommodate the full complexity of multi-layer finishing processes, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to specify finishing options early in the design process and confirm tooling lead times before finalizing the project timeline. Instead of adding finishing options as an afterthought—"Can we add foil stamping to the logo?"—procurement teams should specify all desired finishing options in the initial design brief and request a detailed timeline breakdown from the supplier. The supplier should provide a timeline that explicitly shows: die manufacturing lead time (5-7 days), material procurement lead time (3-5 days), sequential processing time (3 days), drying and curing time (3 days), quality control time (1.5 days), equipment availability buffer (4-8 days), and expected rework buffer (2-5 days). The total timeline for three finishing options is 21-28 days, not 3-6 days. By understanding the true timeline impact of finishing options and planning accordingly, procurement teams can avoid the costly surprises that arise when "add foil stamping and embossing" is interpreted as "add 3 days to the timeline" instead of "add 3 weeks to the timeline."

The supplier's perspective on finishing complexity is fundamentally different from the buyer's perspective. For buyers, finishing options are aesthetic enhancements that make the product more premium and visually appealing. For suppliers, finishing options are sequential manufacturing processes that introduce tooling dependencies, drying time constraints, quality control checkpoints, and rework risks. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that finishing options add incrementally to the timeline, while suppliers know that finishing options multiply the timeline due to sequential dependencies. The gap between these assumptions is 2-3 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for the fixed time components of each finishing option, procurement teams can bridge this gap and plan realistic timelines that account for the full complexity of multi-layer finishing processes.

The equipment availability constraint is another factor that multiplies timeline impact. Not all finishing equipment is available in-house at every packaging supplier. Foil stamping and embossing require specialized presses that are expensive to purchase and maintain, so many packaging suppliers outsource these processes to specialist finishing houses. When a supplier outsources a finishing process, they must coordinate with the finishing house's production schedule, which adds 3-5 days to the timeline for each finishing process that is outsourced. If foil stamping and embossing are both outsourced, the cumulative timeline impact is 6-10 days, not including the transportation time to and from the finishing house. Soft touch laminate is typically applied in-house, but the laminating equipment has limited capacity and must be scheduled in advance. If the laminating equipment is fully booked when the embossed sheets are ready, the supplier must wait 2-3 days for an available slot. The cumulative equipment availability delay for three finishing options can be 8-13 days, depending on the supplier's in-house capabilities and the external finishing house's production schedule.

The rejection and rework risk increases significantly with each additional finishing option. A single-layer print job has a rejection rate of 2-5%, meaning that 2-5% of the printed sheets will be rejected due to quality issues and must be reprinted. A two-layer finishing job (print + foil stamping) has a rejection rate of 5-10%, because quality issues can occur at either the printing stage or the foil stamping stage. A three-layer finishing job (print + foil stamping + embossing) has a rejection rate of 10-15%, because quality issues can occur at any of the three stages. A four-layer finishing job (print + foil stamping + embossing + laminate) has a rejection rate of 15-20%. Each rejected sheet must be reprinted, re-foil stamped, re-embossed, and re-laminated, which adds 3-7 days to the timeline for each rework cycle. The probability of at least one rework cycle increases with the number of finishing options. For a single-layer print job, the probability of rework is 2-5%. For a four-layer finishing job, the probability of rework is 50-70%. The expected timeline impact of rework for a four-layer finishing job is 2-5 days, which must be added to the base timeline to calculate the realistic delivery date.

The compounding effect of these fixed time components is what causes the non-linear relationship between number of finishing options and total lead time. A single finishing option (foil stamping only) adds 7-10 days to the base production timeline: 5-7 days for die manufacturing, 1 day for machine setup and processing, 1 day for drying, 0.5 days for quality control. Two finishing options (foil stamping + embossing) add 14-21 days to the base production timeline: 7-10 days for die manufacturing (both dies ordered simultaneously), 2 days for sequential processing, 2 days for drying, 1 day for quality control, 2-6 days for equipment availability delays. Three finishing options (foil stamping + embossing + soft touch laminate) add 21-28 days to the base production timeline: 7-10 days for tooling and material procurement, 3 days for sequential processing, 3 days for drying, 1.5 days for quality control, 4-8 days for equipment availability delays, 2-5 days for expected rework. The timeline impact is not linear (7 days, 14 days, 21 days)—it is multiplicative (7 days, 14-21 days, 21-28 days) because the fixed time components compound at each stage.

When evaluating finishing options for custom corporate gift projects, it's essential to understand how sequential processing requirements, tooling lead times, and quality control checkpoints interact to create non-linear timeline impacts. For comprehensive guidance on structuring realistic timelines that accommodate the full complexity of multi-layer finishing processes, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to specify finishing options early in the design process and confirm tooling lead times before finalizing the project timeline. Instead of adding finishing options as an afterthought—"Can we add foil stamping to the logo?"—procurement teams should specify all desired finishing options in the initial design brief and request a detailed timeline breakdown from the supplier. The supplier should provide a timeline that explicitly shows: die manufacturing lead time (5-7 days), material procurement lead time (3-5 days), sequential processing time (3 days), drying and curing time (3 days), quality control time (1.5 days), equipment availability buffer (4-8 days), and expected rework buffer (2-5 days). The total timeline for three finishing options is 21-28 days, not 3-6 days. By understanding the true timeline impact of finishing options and planning accordingly, procurement teams can avoid the costly surprises that arise when "add foil stamping and embossing" is interpreted as "add 3 days to the timeline" instead of "add 3 weeks to the timeline."

The supplier's perspective on finishing complexity is fundamentally different from the buyer's perspective. For buyers, finishing options are aesthetic enhancements that make the product more premium and visually appealing. For suppliers, finishing options are sequential manufacturing processes that introduce tooling dependencies, drying time constraints, quality control checkpoints, and rework risks. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that finishing options add incrementally to the timeline, while suppliers know that finishing options multiply the timeline due to sequential dependencies. The gap between these assumptions is 2-3 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for the fixed time components of each finishing option, procurement teams can bridge this gap and plan realistic timelines that account for the full complexity of multi-layer finishing processes.

You May Also Like

Rigid Box vs. Corrugated Mailer: Which Material Suits Your Premium Corporate Gifts?

A deep dive into the structural integrity, cost implications, and unboxing experience of rigid boxes versus corrugated mailers for high-end corporate gifting.

Foil Stamping vs. UV Spot: Elevating Your Brand Logo on Custom Gift Boxes

A technical comparison of hot foil stamping and UV spot varnish, analyzing visual impact, durability, and production costs for branded corporate packaging.