Back to BlogLead Time

Why Your 'Approved' Corporate Gift Box Design Isn't Cleared for UK/EU Production

2026-01-13

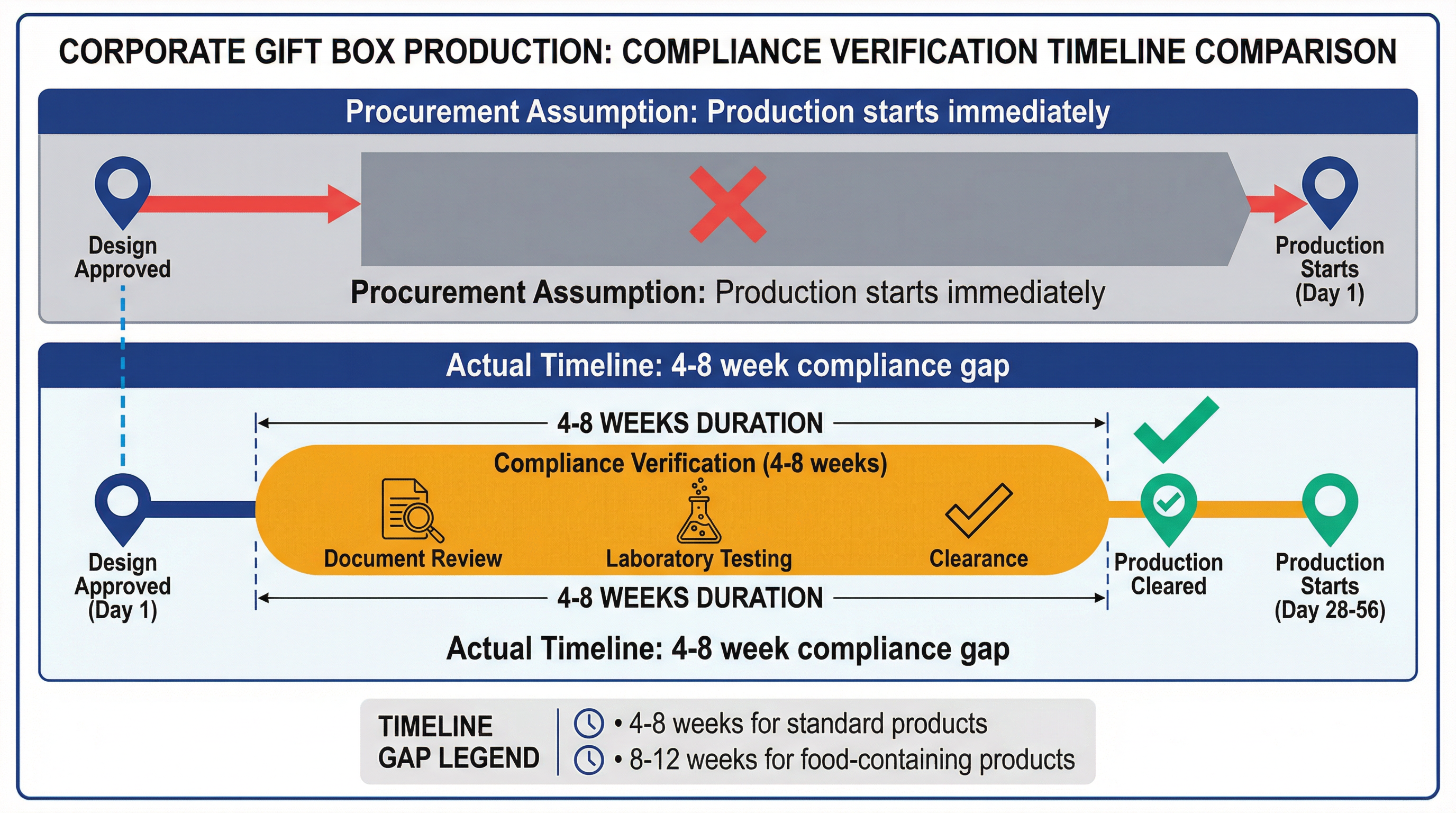

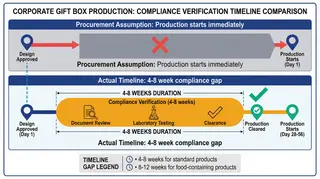

When procurement teams receive final design approval from their internal stakeholders, there's a natural assumption that the supplier can immediately begin production. The design has been reviewed, the sample has been approved, and the timeline clock starts ticking. In practice, the gap between "design approved" and "production cleared for market" exists because of regulatory compliance verification—specifically, the requirement to verify that packaging materials, food contact surfaces, and product components meet UK/EU market-specific requirements before production can legally commence. This gap is rarely communicated clearly in initial quotes, and it's almost never reflected in the "production lead time" figure that procurement teams use for internal planning. The result is a systematic underestimation of total project duration by 4-8 weeks, depending on the complexity of the gift box components and the specific market requirements.

The misjudgment begins with how "design approved" is interpreted. For procurement teams, "design approved" means the internal stakeholders have signed off on the aesthetics, branding, and functional specifications. The assumption is that the supplier will immediately begin procuring materials and scheduling production capacity. For suppliers operating in regulated markets like the UK and EU, "design approved" means the commercial specifications have been agreed upon, but production cannot begin until the design has been verified against market-specific regulatory requirements. This is not a bureaucratic delay—it's a fundamental legal requirement. Suppliers cannot commit to production without first confirming that the packaging materials, printing inks, adhesives, ribbons, and any food contact surfaces comply with UK/EU regulations. The compliance verification process serves as proof that the product is legal to manufacture and sell in the target market.

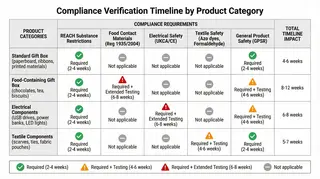

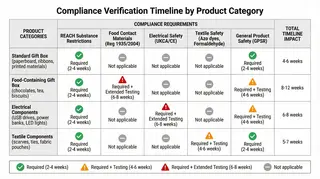

The standard compliance verification timeline for corporate gift boxes is 4-8 weeks, depending on the complexity of the components and whether laboratory testing is required. These timelines are industry-standard across UK/EU manufacturing, and they exist for sound legal reasons. A corporate gift box containing food items, printed packaging, textile ribbons, and branded inserts might require verification against REACH substance restrictions, food contact materials regulations, heavy metals limits, and general product safety requirements. The supplier cannot absorb the risk of producing 5,000 units that fail compliance verification and cannot be legally sold in the UK/EU market. The compliance verification phase is not optional—it's a mandatory step that occurs after design approval and before production clearance.

The timeline impact of compliance verification is rarely visible in supplier quotes. When a supplier quotes "8 weeks production lead time," that figure refers to the time required to manufacture the goods after materials are procured and production is cleared to begin. It does not include the time required to verify regulatory compliance, conduct laboratory testing if needed, and obtain clearance documentation. For procurement teams operating in large organizations, the internal assumption is that "design approved" equals "production ready." The reality is that compliance verification adds 4-8 weeks to the timeline before production can legally begin. This delay is invisible to the procurement team because it occurs before the supplier's "production lead time" clock starts ticking.

The compounding effect occurs when procurement teams use the quoted "production lead time" as the basis for their internal delivery timeline. A procurement manager receives design approval on January 10th and calculates a delivery date of March 7th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for March 15th. The manager assumes production begins on January 10th, the day the design was approved. In reality, production begins on February 14th, after compliance verification is completed and production clearance is issued. The actual delivery date is April 11th, not March 7th. The procurement manager has underestimated the timeline by 5 weeks, and the corporate event is now at risk.

The compliance verification process involves multiple steps that are invisible to procurement teams but critical to the timeline. When the procurement team approves the final design, the supplier initiates compliance verification by submitting material specifications to their compliance team. The compliance team reviews the packaging materials (paperboard, plastic inserts, printing inks, adhesives), textile components (ribbons, fabric linings), and any food contact surfaces against UK/EU regulatory databases. If all materials are pre-verified and already in the supplier's approved materials library, the verification process takes 3-5 business days. If any materials are new or require laboratory testing, the verification process extends to 4-8 weeks. The laboratory testing itself takes 2-4 weeks, and the results must be reviewed and documented before production clearance can be issued. This entire workflow occurs before the supplier's "production lead time" begins.

The standard compliance verification timeline for corporate gift boxes is 4-8 weeks, depending on the complexity of the components and whether laboratory testing is required. These timelines are industry-standard across UK/EU manufacturing, and they exist for sound legal reasons. A corporate gift box containing food items, printed packaging, textile ribbons, and branded inserts might require verification against REACH substance restrictions, food contact materials regulations, heavy metals limits, and general product safety requirements. The supplier cannot absorb the risk of producing 5,000 units that fail compliance verification and cannot be legally sold in the UK/EU market. The compliance verification phase is not optional—it's a mandatory step that occurs after design approval and before production clearance.

The timeline impact of compliance verification is rarely visible in supplier quotes. When a supplier quotes "8 weeks production lead time," that figure refers to the time required to manufacture the goods after materials are procured and production is cleared to begin. It does not include the time required to verify regulatory compliance, conduct laboratory testing if needed, and obtain clearance documentation. For procurement teams operating in large organizations, the internal assumption is that "design approved" equals "production ready." The reality is that compliance verification adds 4-8 weeks to the timeline before production can legally begin. This delay is invisible to the procurement team because it occurs before the supplier's "production lead time" clock starts ticking.

The compounding effect occurs when procurement teams use the quoted "production lead time" as the basis for their internal delivery timeline. A procurement manager receives design approval on January 10th and calculates a delivery date of March 7th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for March 15th. The manager assumes production begins on January 10th, the day the design was approved. In reality, production begins on February 14th, after compliance verification is completed and production clearance is issued. The actual delivery date is April 11th, not March 7th. The procurement manager has underestimated the timeline by 5 weeks, and the corporate event is now at risk.

The compliance verification process involves multiple steps that are invisible to procurement teams but critical to the timeline. When the procurement team approves the final design, the supplier initiates compliance verification by submitting material specifications to their compliance team. The compliance team reviews the packaging materials (paperboard, plastic inserts, printing inks, adhesives), textile components (ribbons, fabric linings), and any food contact surfaces against UK/EU regulatory databases. If all materials are pre-verified and already in the supplier's approved materials library, the verification process takes 3-5 business days. If any materials are new or require laboratory testing, the verification process extends to 4-8 weeks. The laboratory testing itself takes 2-4 weeks, and the results must be reviewed and documented before production clearance can be issued. This entire workflow occurs before the supplier's "production lead time" begins.

The risk of timeline slippage increases significantly when corporate gift boxes contain food items or food contact surfaces. UK/EU regulations require that any material intended to come into contact with food must be verified against Regulation 1935/2004, which governs food contact materials. This includes not only the inner packaging that directly touches food items, but also the outer packaging that provides indirect contact. A corporate gift box containing chocolates, tea, or biscuits requires food contact materials verification for the inner tray, the paperboard box, the printing inks used on the interior surfaces, and any adhesives used in assembly. The verification process requires laboratory testing to confirm that the materials do not migrate harmful substances into the food. The testing timeline is 3-6 weeks, and if the results show non-compliance, the supplier must source alternative materials and repeat the testing process. The total timeline impact can extend to 8-12 weeks if the initial materials fail compliance testing.

The hidden cost of compliance verification extends beyond timeline slippage—it affects material sourcing decisions. Suppliers plan their material procurement based on confirmed compliance clearance. When a procurement team approves a design but the materials have not yet been verified for compliance, the supplier cannot order materials. The material supplier requires confirmation that the materials meet regulatory requirements before accepting the order. When the compliance verification finally completes, the material supplier may no longer have the materials in stock, requiring additional lead time for production. The procurement team has not only lost 4-8 weeks to compliance verification—they have lost an additional 2-4 weeks to material procurement delays. The total timeline impact is 6-12 weeks, not the 4-8 weeks that the procurement team expected.

The compliance verification requirements vary significantly by market and product category. UK market requirements differ from EU requirements in several key areas, particularly after Brexit. Products sold in the UK must comply with UKCA marking requirements, while products sold in the EU must comply with CE marking requirements. Corporate gift boxes containing electrical components (USB drives, power banks, LED lights) require additional compliance verification against electrical safety regulations. Gift boxes containing textile components (scarves, ties, fabric pouches) require verification against textile safety regulations, including restrictions on azo dyes and formaldehyde. Gift boxes containing children's items require verification against toy safety regulations, including restrictions on small parts and phthalates. Each additional compliance requirement adds 1-2 weeks to the verification timeline, and the cumulative effect can extend the pre-production phase by 8-12 weeks.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 4-8 weeks for standard corporate gift boxes, and by 8-12 weeks for gift boxes containing food items or multiple regulated components. A project that was expected to take 9 weeks (8 weeks production + 1 week shipping) actually takes 13-17 weeks (4-8 weeks compliance verification + 8 weeks production + 1 week shipping). The procurement team has missed their internal deadline by 4-8 weeks, and they are now scrambling to explain the delay to their stakeholders. The supplier has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 4-8 weeks of compliance verification time required to clear the design for production.

Understanding the distinction between design approval and production clearance is essential when planning realistic timelines for corporate gift programs. For comprehensive guidance on [the full spectrum of factors affecting project duration](/resources/leadtime-production-guide) from initial order through final distribution, procurement teams should account for all pre-production phases including compliance verification, material sourcing, and production queue positioning.

The supplier's perspective on compliance verification is fundamentally different from the procurement team's perspective. For procurement teams, compliance verification is an administrative formality that should take a few days at most. For suppliers, compliance verification is a legal requirement that determines whether the product can be legally manufactured and sold in the target market. The disconnect between these perspectives is where timeline misjudgments occur. Procurement teams assume that "design approved" means "production ready," while suppliers assume that "design approved" means "awaiting compliance clearance." The gap between these assumptions is 4-8 weeks for standard products, and 8-12 weeks for products containing food items or multiple regulated components. By understanding the supplier's perspective and explicitly accounting for compliance verification time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from design approval to final delivery.

The financial discipline required to initiate compliance verification promptly is often underestimated by procurement teams. In large organizations, the approval process for releasing design specifications to the supplier can be slow, especially when multiple stakeholders need to review and approve the final design. Procurement teams should anticipate these delays and initiate the compliance verification process in parallel with internal design approval, not after. By pre-approving the compliance verification budget and having the specifications ready to release immediately upon design approval, procurement teams can eliminate 1-2 weeks of administrative delay. This small operational improvement can prevent significant timeline slippage and ensure that production clearance is issued on schedule.

The regulatory landscape for corporate gift products is constantly evolving, and procurement teams must stay informed about new requirements that may affect their timelines. The General Product Safety Regulation (GPSR), which came into effect in December 2024, introduced new compliance requirements for products sold in the EU market, including mandatory product identification, safety warnings in local languages, and appointment of an EU-based Responsible Person for non-EU manufacturers. These new requirements add 1-2 weeks to the compliance verification timeline for products that were previously exempt from specific safety regulations. Procurement teams that are unaware of these new requirements will consistently underestimate timelines by 1-2 weeks, and they will be caught off guard when suppliers request additional documentation or testing to meet the new requirements.

The risk of timeline slippage increases significantly when corporate gift boxes contain food items or food contact surfaces. UK/EU regulations require that any material intended to come into contact with food must be verified against Regulation 1935/2004, which governs food contact materials. This includes not only the inner packaging that directly touches food items, but also the outer packaging that provides indirect contact. A corporate gift box containing chocolates, tea, or biscuits requires food contact materials verification for the inner tray, the paperboard box, the printing inks used on the interior surfaces, and any adhesives used in assembly. The verification process requires laboratory testing to confirm that the materials do not migrate harmful substances into the food. The testing timeline is 3-6 weeks, and if the results show non-compliance, the supplier must source alternative materials and repeat the testing process. The total timeline impact can extend to 8-12 weeks if the initial materials fail compliance testing.

The hidden cost of compliance verification extends beyond timeline slippage—it affects material sourcing decisions. Suppliers plan their material procurement based on confirmed compliance clearance. When a procurement team approves a design but the materials have not yet been verified for compliance, the supplier cannot order materials. The material supplier requires confirmation that the materials meet regulatory requirements before accepting the order. When the compliance verification finally completes, the material supplier may no longer have the materials in stock, requiring additional lead time for production. The procurement team has not only lost 4-8 weeks to compliance verification—they have lost an additional 2-4 weeks to material procurement delays. The total timeline impact is 6-12 weeks, not the 4-8 weeks that the procurement team expected.

The compliance verification requirements vary significantly by market and product category. UK market requirements differ from EU requirements in several key areas, particularly after Brexit. Products sold in the UK must comply with UKCA marking requirements, while products sold in the EU must comply with CE marking requirements. Corporate gift boxes containing electrical components (USB drives, power banks, LED lights) require additional compliance verification against electrical safety regulations. Gift boxes containing textile components (scarves, ties, fabric pouches) require verification against textile safety regulations, including restrictions on azo dyes and formaldehyde. Gift boxes containing children's items require verification against toy safety regulations, including restrictions on small parts and phthalates. Each additional compliance requirement adds 1-2 weeks to the verification timeline, and the cumulative effect can extend the pre-production phase by 8-12 weeks.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 4-8 weeks for standard corporate gift boxes, and by 8-12 weeks for gift boxes containing food items or multiple regulated components. A project that was expected to take 9 weeks (8 weeks production + 1 week shipping) actually takes 13-17 weeks (4-8 weeks compliance verification + 8 weeks production + 1 week shipping). The procurement team has missed their internal deadline by 4-8 weeks, and they are now scrambling to explain the delay to their stakeholders. The supplier has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 4-8 weeks of compliance verification time required to clear the design for production.

Understanding the distinction between design approval and production clearance is essential when planning realistic timelines for corporate gift programs. For comprehensive guidance on [the full spectrum of factors affecting project duration](/resources/leadtime-production-guide) from initial order through final distribution, procurement teams should account for all pre-production phases including compliance verification, material sourcing, and production queue positioning.

The supplier's perspective on compliance verification is fundamentally different from the procurement team's perspective. For procurement teams, compliance verification is an administrative formality that should take a few days at most. For suppliers, compliance verification is a legal requirement that determines whether the product can be legally manufactured and sold in the target market. The disconnect between these perspectives is where timeline misjudgments occur. Procurement teams assume that "design approved" means "production ready," while suppliers assume that "design approved" means "awaiting compliance clearance." The gap between these assumptions is 4-8 weeks for standard products, and 8-12 weeks for products containing food items or multiple regulated components. By understanding the supplier's perspective and explicitly accounting for compliance verification time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from design approval to final delivery.

The financial discipline required to initiate compliance verification promptly is often underestimated by procurement teams. In large organizations, the approval process for releasing design specifications to the supplier can be slow, especially when multiple stakeholders need to review and approve the final design. Procurement teams should anticipate these delays and initiate the compliance verification process in parallel with internal design approval, not after. By pre-approving the compliance verification budget and having the specifications ready to release immediately upon design approval, procurement teams can eliminate 1-2 weeks of administrative delay. This small operational improvement can prevent significant timeline slippage and ensure that production clearance is issued on schedule.

The regulatory landscape for corporate gift products is constantly evolving, and procurement teams must stay informed about new requirements that may affect their timelines. The General Product Safety Regulation (GPSR), which came into effect in December 2024, introduced new compliance requirements for products sold in the EU market, including mandatory product identification, safety warnings in local languages, and appointment of an EU-based Responsible Person for non-EU manufacturers. These new requirements add 1-2 weeks to the compliance verification timeline for products that were previously exempt from specific safety regulations. Procurement teams that are unaware of these new requirements will consistently underestimate timelines by 1-2 weeks, and they will be caught off guard when suppliers request additional documentation or testing to meet the new requirements.

The standard compliance verification timeline for corporate gift boxes is 4-8 weeks, depending on the complexity of the components and whether laboratory testing is required. These timelines are industry-standard across UK/EU manufacturing, and they exist for sound legal reasons. A corporate gift box containing food items, printed packaging, textile ribbons, and branded inserts might require verification against REACH substance restrictions, food contact materials regulations, heavy metals limits, and general product safety requirements. The supplier cannot absorb the risk of producing 5,000 units that fail compliance verification and cannot be legally sold in the UK/EU market. The compliance verification phase is not optional—it's a mandatory step that occurs after design approval and before production clearance.

The timeline impact of compliance verification is rarely visible in supplier quotes. When a supplier quotes "8 weeks production lead time," that figure refers to the time required to manufacture the goods after materials are procured and production is cleared to begin. It does not include the time required to verify regulatory compliance, conduct laboratory testing if needed, and obtain clearance documentation. For procurement teams operating in large organizations, the internal assumption is that "design approved" equals "production ready." The reality is that compliance verification adds 4-8 weeks to the timeline before production can legally begin. This delay is invisible to the procurement team because it occurs before the supplier's "production lead time" clock starts ticking.

The compounding effect occurs when procurement teams use the quoted "production lead time" as the basis for their internal delivery timeline. A procurement manager receives design approval on January 10th and calculates a delivery date of March 7th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for March 15th. The manager assumes production begins on January 10th, the day the design was approved. In reality, production begins on February 14th, after compliance verification is completed and production clearance is issued. The actual delivery date is April 11th, not March 7th. The procurement manager has underestimated the timeline by 5 weeks, and the corporate event is now at risk.

The compliance verification process involves multiple steps that are invisible to procurement teams but critical to the timeline. When the procurement team approves the final design, the supplier initiates compliance verification by submitting material specifications to their compliance team. The compliance team reviews the packaging materials (paperboard, plastic inserts, printing inks, adhesives), textile components (ribbons, fabric linings), and any food contact surfaces against UK/EU regulatory databases. If all materials are pre-verified and already in the supplier's approved materials library, the verification process takes 3-5 business days. If any materials are new or require laboratory testing, the verification process extends to 4-8 weeks. The laboratory testing itself takes 2-4 weeks, and the results must be reviewed and documented before production clearance can be issued. This entire workflow occurs before the supplier's "production lead time" begins.

The standard compliance verification timeline for corporate gift boxes is 4-8 weeks, depending on the complexity of the components and whether laboratory testing is required. These timelines are industry-standard across UK/EU manufacturing, and they exist for sound legal reasons. A corporate gift box containing food items, printed packaging, textile ribbons, and branded inserts might require verification against REACH substance restrictions, food contact materials regulations, heavy metals limits, and general product safety requirements. The supplier cannot absorb the risk of producing 5,000 units that fail compliance verification and cannot be legally sold in the UK/EU market. The compliance verification phase is not optional—it's a mandatory step that occurs after design approval and before production clearance.

The timeline impact of compliance verification is rarely visible in supplier quotes. When a supplier quotes "8 weeks production lead time," that figure refers to the time required to manufacture the goods after materials are procured and production is cleared to begin. It does not include the time required to verify regulatory compliance, conduct laboratory testing if needed, and obtain clearance documentation. For procurement teams operating in large organizations, the internal assumption is that "design approved" equals "production ready." The reality is that compliance verification adds 4-8 weeks to the timeline before production can legally begin. This delay is invisible to the procurement team because it occurs before the supplier's "production lead time" clock starts ticking.

The compounding effect occurs when procurement teams use the quoted "production lead time" as the basis for their internal delivery timeline. A procurement manager receives design approval on January 10th and calculates a delivery date of March 7th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for March 15th. The manager assumes production begins on January 10th, the day the design was approved. In reality, production begins on February 14th, after compliance verification is completed and production clearance is issued. The actual delivery date is April 11th, not March 7th. The procurement manager has underestimated the timeline by 5 weeks, and the corporate event is now at risk.

The compliance verification process involves multiple steps that are invisible to procurement teams but critical to the timeline. When the procurement team approves the final design, the supplier initiates compliance verification by submitting material specifications to their compliance team. The compliance team reviews the packaging materials (paperboard, plastic inserts, printing inks, adhesives), textile components (ribbons, fabric linings), and any food contact surfaces against UK/EU regulatory databases. If all materials are pre-verified and already in the supplier's approved materials library, the verification process takes 3-5 business days. If any materials are new or require laboratory testing, the verification process extends to 4-8 weeks. The laboratory testing itself takes 2-4 weeks, and the results must be reviewed and documented before production clearance can be issued. This entire workflow occurs before the supplier's "production lead time" begins.

The risk of timeline slippage increases significantly when corporate gift boxes contain food items or food contact surfaces. UK/EU regulations require that any material intended to come into contact with food must be verified against Regulation 1935/2004, which governs food contact materials. This includes not only the inner packaging that directly touches food items, but also the outer packaging that provides indirect contact. A corporate gift box containing chocolates, tea, or biscuits requires food contact materials verification for the inner tray, the paperboard box, the printing inks used on the interior surfaces, and any adhesives used in assembly. The verification process requires laboratory testing to confirm that the materials do not migrate harmful substances into the food. The testing timeline is 3-6 weeks, and if the results show non-compliance, the supplier must source alternative materials and repeat the testing process. The total timeline impact can extend to 8-12 weeks if the initial materials fail compliance testing.

The hidden cost of compliance verification extends beyond timeline slippage—it affects material sourcing decisions. Suppliers plan their material procurement based on confirmed compliance clearance. When a procurement team approves a design but the materials have not yet been verified for compliance, the supplier cannot order materials. The material supplier requires confirmation that the materials meet regulatory requirements before accepting the order. When the compliance verification finally completes, the material supplier may no longer have the materials in stock, requiring additional lead time for production. The procurement team has not only lost 4-8 weeks to compliance verification—they have lost an additional 2-4 weeks to material procurement delays. The total timeline impact is 6-12 weeks, not the 4-8 weeks that the procurement team expected.

The compliance verification requirements vary significantly by market and product category. UK market requirements differ from EU requirements in several key areas, particularly after Brexit. Products sold in the UK must comply with UKCA marking requirements, while products sold in the EU must comply with CE marking requirements. Corporate gift boxes containing electrical components (USB drives, power banks, LED lights) require additional compliance verification against electrical safety regulations. Gift boxes containing textile components (scarves, ties, fabric pouches) require verification against textile safety regulations, including restrictions on azo dyes and formaldehyde. Gift boxes containing children's items require verification against toy safety regulations, including restrictions on small parts and phthalates. Each additional compliance requirement adds 1-2 weeks to the verification timeline, and the cumulative effect can extend the pre-production phase by 8-12 weeks.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 4-8 weeks for standard corporate gift boxes, and by 8-12 weeks for gift boxes containing food items or multiple regulated components. A project that was expected to take 9 weeks (8 weeks production + 1 week shipping) actually takes 13-17 weeks (4-8 weeks compliance verification + 8 weeks production + 1 week shipping). The procurement team has missed their internal deadline by 4-8 weeks, and they are now scrambling to explain the delay to their stakeholders. The supplier has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 4-8 weeks of compliance verification time required to clear the design for production.

Understanding the distinction between design approval and production clearance is essential when planning realistic timelines for corporate gift programs. For comprehensive guidance on [the full spectrum of factors affecting project duration](/resources/leadtime-production-guide) from initial order through final distribution, procurement teams should account for all pre-production phases including compliance verification, material sourcing, and production queue positioning.

The supplier's perspective on compliance verification is fundamentally different from the procurement team's perspective. For procurement teams, compliance verification is an administrative formality that should take a few days at most. For suppliers, compliance verification is a legal requirement that determines whether the product can be legally manufactured and sold in the target market. The disconnect between these perspectives is where timeline misjudgments occur. Procurement teams assume that "design approved" means "production ready," while suppliers assume that "design approved" means "awaiting compliance clearance." The gap between these assumptions is 4-8 weeks for standard products, and 8-12 weeks for products containing food items or multiple regulated components. By understanding the supplier's perspective and explicitly accounting for compliance verification time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from design approval to final delivery.

The financial discipline required to initiate compliance verification promptly is often underestimated by procurement teams. In large organizations, the approval process for releasing design specifications to the supplier can be slow, especially when multiple stakeholders need to review and approve the final design. Procurement teams should anticipate these delays and initiate the compliance verification process in parallel with internal design approval, not after. By pre-approving the compliance verification budget and having the specifications ready to release immediately upon design approval, procurement teams can eliminate 1-2 weeks of administrative delay. This small operational improvement can prevent significant timeline slippage and ensure that production clearance is issued on schedule.

The regulatory landscape for corporate gift products is constantly evolving, and procurement teams must stay informed about new requirements that may affect their timelines. The General Product Safety Regulation (GPSR), which came into effect in December 2024, introduced new compliance requirements for products sold in the EU market, including mandatory product identification, safety warnings in local languages, and appointment of an EU-based Responsible Person for non-EU manufacturers. These new requirements add 1-2 weeks to the compliance verification timeline for products that were previously exempt from specific safety regulations. Procurement teams that are unaware of these new requirements will consistently underestimate timelines by 1-2 weeks, and they will be caught off guard when suppliers request additional documentation or testing to meet the new requirements.

The risk of timeline slippage increases significantly when corporate gift boxes contain food items or food contact surfaces. UK/EU regulations require that any material intended to come into contact with food must be verified against Regulation 1935/2004, which governs food contact materials. This includes not only the inner packaging that directly touches food items, but also the outer packaging that provides indirect contact. A corporate gift box containing chocolates, tea, or biscuits requires food contact materials verification for the inner tray, the paperboard box, the printing inks used on the interior surfaces, and any adhesives used in assembly. The verification process requires laboratory testing to confirm that the materials do not migrate harmful substances into the food. The testing timeline is 3-6 weeks, and if the results show non-compliance, the supplier must source alternative materials and repeat the testing process. The total timeline impact can extend to 8-12 weeks if the initial materials fail compliance testing.

The hidden cost of compliance verification extends beyond timeline slippage—it affects material sourcing decisions. Suppliers plan their material procurement based on confirmed compliance clearance. When a procurement team approves a design but the materials have not yet been verified for compliance, the supplier cannot order materials. The material supplier requires confirmation that the materials meet regulatory requirements before accepting the order. When the compliance verification finally completes, the material supplier may no longer have the materials in stock, requiring additional lead time for production. The procurement team has not only lost 4-8 weeks to compliance verification—they have lost an additional 2-4 weeks to material procurement delays. The total timeline impact is 6-12 weeks, not the 4-8 weeks that the procurement team expected.

The compliance verification requirements vary significantly by market and product category. UK market requirements differ from EU requirements in several key areas, particularly after Brexit. Products sold in the UK must comply with UKCA marking requirements, while products sold in the EU must comply with CE marking requirements. Corporate gift boxes containing electrical components (USB drives, power banks, LED lights) require additional compliance verification against electrical safety regulations. Gift boxes containing textile components (scarves, ties, fabric pouches) require verification against textile safety regulations, including restrictions on azo dyes and formaldehyde. Gift boxes containing children's items require verification against toy safety regulations, including restrictions on small parts and phthalates. Each additional compliance requirement adds 1-2 weeks to the verification timeline, and the cumulative effect can extend the pre-production phase by 8-12 weeks.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 4-8 weeks for standard corporate gift boxes, and by 8-12 weeks for gift boxes containing food items or multiple regulated components. A project that was expected to take 9 weeks (8 weeks production + 1 week shipping) actually takes 13-17 weeks (4-8 weeks compliance verification + 8 weeks production + 1 week shipping). The procurement team has missed their internal deadline by 4-8 weeks, and they are now scrambling to explain the delay to their stakeholders. The supplier has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 4-8 weeks of compliance verification time required to clear the design for production.

Understanding the distinction between design approval and production clearance is essential when planning realistic timelines for corporate gift programs. For comprehensive guidance on [the full spectrum of factors affecting project duration](/resources/leadtime-production-guide) from initial order through final distribution, procurement teams should account for all pre-production phases including compliance verification, material sourcing, and production queue positioning.

The supplier's perspective on compliance verification is fundamentally different from the procurement team's perspective. For procurement teams, compliance verification is an administrative formality that should take a few days at most. For suppliers, compliance verification is a legal requirement that determines whether the product can be legally manufactured and sold in the target market. The disconnect between these perspectives is where timeline misjudgments occur. Procurement teams assume that "design approved" means "production ready," while suppliers assume that "design approved" means "awaiting compliance clearance." The gap between these assumptions is 4-8 weeks for standard products, and 8-12 weeks for products containing food items or multiple regulated components. By understanding the supplier's perspective and explicitly accounting for compliance verification time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from design approval to final delivery.

The financial discipline required to initiate compliance verification promptly is often underestimated by procurement teams. In large organizations, the approval process for releasing design specifications to the supplier can be slow, especially when multiple stakeholders need to review and approve the final design. Procurement teams should anticipate these delays and initiate the compliance verification process in parallel with internal design approval, not after. By pre-approving the compliance verification budget and having the specifications ready to release immediately upon design approval, procurement teams can eliminate 1-2 weeks of administrative delay. This small operational improvement can prevent significant timeline slippage and ensure that production clearance is issued on schedule.

The regulatory landscape for corporate gift products is constantly evolving, and procurement teams must stay informed about new requirements that may affect their timelines. The General Product Safety Regulation (GPSR), which came into effect in December 2024, introduced new compliance requirements for products sold in the EU market, including mandatory product identification, safety warnings in local languages, and appointment of an EU-based Responsible Person for non-EU manufacturers. These new requirements add 1-2 weeks to the compliance verification timeline for products that were previously exempt from specific safety regulations. Procurement teams that are unaware of these new requirements will consistently underestimate timelines by 1-2 weeks, and they will be caught off guard when suppliers request additional documentation or testing to meet the new requirements.You May Also Like

Rigid Box vs. Corrugated Mailer: Which Material Suits Your Premium Corporate Gifts?

A deep dive into the structural integrity, cost implications, and unboxing experience of rigid boxes versus corrugated mailers for high-end corporate gifting.

Foil Stamping vs. UV Spot: Elevating Your Brand Logo on Custom Gift Boxes

A technical comparison of hot foil stamping and UV spot varnish, analyzing visual impact, durability, and production costs for branded corporate packaging.