Back to BlogCustomization Process

Why 'Design Approved' Doesn't Mean Production Can Start on Your Corporate Gift Boxes

2026-01-25

When procurement teams receive design approval confirmation from their supplier, there's a natural assumption that production will begin immediately. The design has been reviewed, the supplier has incorporated feedback, and the final proof has been signed off. The procurement manager updates their internal timeline, communicates the expected delivery date to stakeholders, and moves on to the next project. In practice, the gap between "design approved by procurement" and "production started" exists because of internal stakeholder alignment—specifically, the sequential approval process that occurs after the initial design is finalized. This gap is rarely visible to the supplier, and it's almost never reflected in the "design approval timeline" that procurement teams use for internal planning. The result is a systematic underestimation of total project duration by 2-4 weeks, depending on the number of internal stakeholders involved and the complexity of their approval requirements.

The misjudgment begins with how "design approved" is interpreted within the buying organization. For procurement teams, "design approved" means that they have reviewed the supplier's design proof, confirmed that it matches the specifications in the purchase order, and provided their sign-off. The assumption is that this approval is sufficient to begin production, because procurement is the primary point of contact with the supplier and holds the authority to approve commercial terms. For suppliers—particularly those manufacturing custom corporate gift boxes—"design approved by procurement" is understood as the first approval in a series of internal approvals that must be completed before production can begin. The supplier knows from experience that the design will need to be reviewed by the marketing team (for brand consistency), the compliance team (for regulatory text), and often an executive sponsor (for strategic messaging). Until all of these approvals are complete, the supplier cannot order materials, schedule production capacity, or begin tooling setup. This is not a bureaucratic delay—it's a fundamental risk management practice. Suppliers cannot commit capital to material procurement and production setup without confirmation that the design has been approved by all relevant stakeholders within the buying organization.

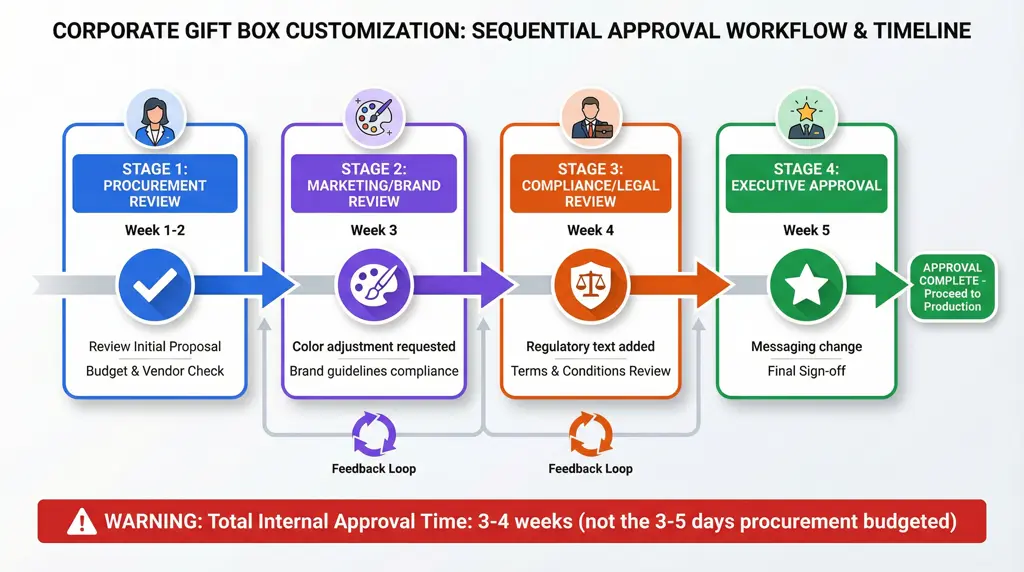

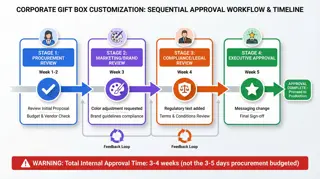

The standard approval workflow for custom corporate gift box projects involves at least three internal stakeholders beyond procurement: the marketing or brand team, the compliance or legal team, and an executive sponsor or budget holder. Each of these stakeholders has a different set of approval criteria, and each sees the design for the first time at their stage in the approval process. The marketing team reviews the design for brand consistency—logo placement, color accuracy, typography, and overall visual alignment with brand guidelines. The compliance team reviews the design for regulatory requirements—product safety warnings, ingredient disclosures, recycling symbols, and any market-specific legal text. The executive sponsor reviews the design for strategic messaging—does the gift reflect the company's values, does it align with the campaign objectives, and does it justify the budget allocation. Each of these reviews can result in revision requests, and each revision request resets the approval timeline.

The timeline impact of sequential approvals is rarely visible in the initial project plan. When a procurement manager places an order for custom corporate gift boxes and receives a design proof from the supplier, they typically allow 3-5 business days for internal review and approval. This timeline assumes that the design will be reviewed and approved by all relevant stakeholders within that window. In reality, the approval process is sequential, not parallel. The procurement manager reviews the design first and provides their approval to the supplier. The supplier then asks, "Has this been approved by your marketing team?" The procurement manager forwards the design to marketing, who reviews it 2-3 days later and requests a color adjustment. The supplier makes the adjustment and sends a revised proof. The procurement manager forwards it to marketing again, who approves it 1-2 days later. The supplier then asks, "Has this been approved by your compliance team?" The procurement manager forwards the design to compliance, who reviews it 3-4 days later and requests additional regulatory text. The supplier makes the adjustment and sends another revised proof. This cycle continues until all stakeholders have approved the design. The total time from "procurement approval" to "all stakeholders approved" is 2-4 weeks, not the 3-5 days that the procurement manager originally budgeted.

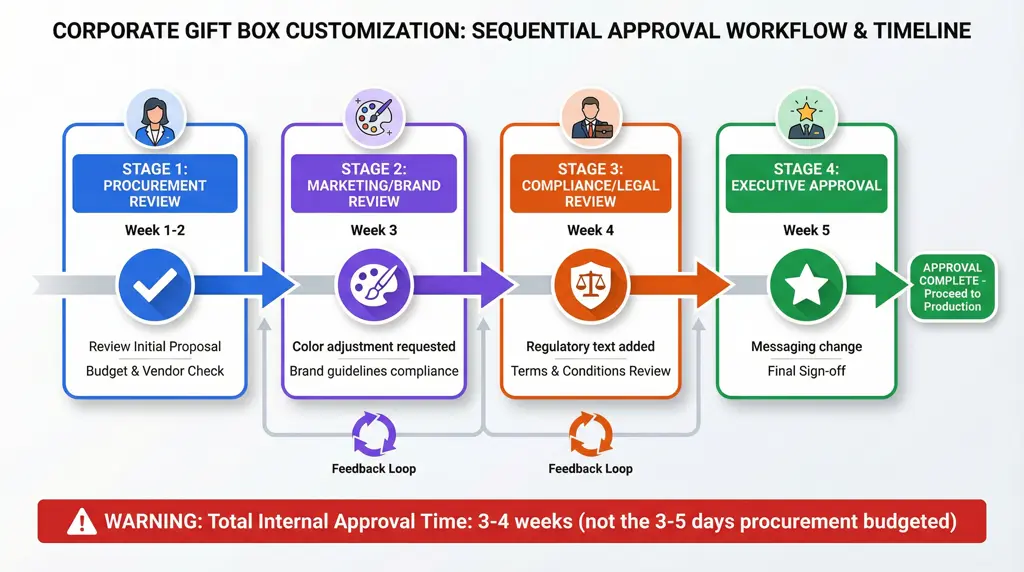

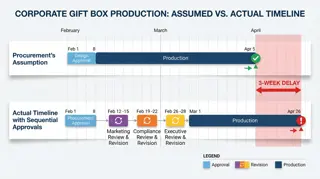

The compounding effect occurs when the procurement manager uses the supplier's "production lead time" as the basis for their internal delivery timeline. A procurement manager places an order on February 1st, receives a design proof on February 5th, approves it on February 8th, and calculates a delivery date of April 5th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for April 15th. The manager assumes production begins on February 8th, the day they approved the design. In reality, production begins on March 1st, after the marketing team requests a logo adjustment (February 12-15), the compliance team requests regulatory text (February 19-22), and the executive sponsor requests a messaging change (February 26-28). The actual delivery date is April 26th, not April 5th. The procurement manager has underestimated the timeline by 3 weeks, and the corporate event is now at risk.

The approval workflow involves multiple steps that are invisible to the supplier but critical to the timeline. When the procurement manager receives the initial design proof, they review it against the purchase order specifications and provide their approval. At this point, the procurement manager believes the design is final and production can begin. The supplier, however, knows from experience that the design will need to be reviewed by other stakeholders. The supplier asks, "Has this been approved by your marketing and compliance teams?" If the procurement manager has not yet circulated the design to these teams, the supplier must wait. The supplier cannot order materials until the design is fully approved, because any changes to the design after materials are ordered will result in waste and additional costs. The supplier also cannot schedule production capacity until the design is approved, because production schedules are planned weeks in advance and any changes to the design will require rescheduling. The supplier is not being difficult—they are protecting both parties from the costly consequences of starting production before the design is truly final.

The timeline impact of sequential approvals is rarely visible in the initial project plan. When a procurement manager places an order for custom corporate gift boxes and receives a design proof from the supplier, they typically allow 3-5 business days for internal review and approval. This timeline assumes that the design will be reviewed and approved by all relevant stakeholders within that window. In reality, the approval process is sequential, not parallel. The procurement manager reviews the design first and provides their approval to the supplier. The supplier then asks, "Has this been approved by your marketing team?" The procurement manager forwards the design to marketing, who reviews it 2-3 days later and requests a color adjustment. The supplier makes the adjustment and sends a revised proof. The procurement manager forwards it to marketing again, who approves it 1-2 days later. The supplier then asks, "Has this been approved by your compliance team?" The procurement manager forwards the design to compliance, who reviews it 3-4 days later and requests additional regulatory text. The supplier makes the adjustment and sends another revised proof. This cycle continues until all stakeholders have approved the design. The total time from "procurement approval" to "all stakeholders approved" is 2-4 weeks, not the 3-5 days that the procurement manager originally budgeted.

The compounding effect occurs when the procurement manager uses the supplier's "production lead time" as the basis for their internal delivery timeline. A procurement manager places an order on February 1st, receives a design proof on February 5th, approves it on February 8th, and calculates a delivery date of April 5th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for April 15th. The manager assumes production begins on February 8th, the day they approved the design. In reality, production begins on March 1st, after the marketing team requests a logo adjustment (February 12-15), the compliance team requests regulatory text (February 19-22), and the executive sponsor requests a messaging change (February 26-28). The actual delivery date is April 26th, not April 5th. The procurement manager has underestimated the timeline by 3 weeks, and the corporate event is now at risk.

The approval workflow involves multiple steps that are invisible to the supplier but critical to the timeline. When the procurement manager receives the initial design proof, they review it against the purchase order specifications and provide their approval. At this point, the procurement manager believes the design is final and production can begin. The supplier, however, knows from experience that the design will need to be reviewed by other stakeholders. The supplier asks, "Has this been approved by your marketing and compliance teams?" If the procurement manager has not yet circulated the design to these teams, the supplier must wait. The supplier cannot order materials until the design is fully approved, because any changes to the design after materials are ordered will result in waste and additional costs. The supplier also cannot schedule production capacity until the design is approved, because production schedules are planned weeks in advance and any changes to the design will require rescheduling. The supplier is not being difficult—they are protecting both parties from the costly consequences of starting production before the design is truly final.

The risk of timeline slippage increases significantly when stakeholders request "minor changes" after the initial design approval. A "minor change" from the stakeholder's perspective—such as adjusting the logo size, changing a color shade, or adding a line of text—is not minor from the supplier's perspective. Each change requires a new design proof, a new round of internal approvals, and potentially a new round of material sourcing if the change affects printing specifications. A logo size adjustment might seem trivial, but it requires the supplier to regenerate the entire print file, create a new proof, and wait for approval from all stakeholders again. A color shade adjustment requires the supplier to create a new color swatch, send it for approval, and potentially adjust the printing process. A text addition requires the supplier to reflow the layout, ensure compliance with regulatory requirements, and create a new proof. Each of these "minor changes" adds 3-7 days to the timeline, and if multiple stakeholders request changes sequentially, the cumulative delay can be 2-3 weeks.

The hidden cost of approval delays extends beyond timeline slippage—it affects material procurement and production queue positioning. Suppliers plan their material procurement based on confirmed designs. When a procurement team approves a design but then requests changes after materials have been ordered, the supplier must either absorb the cost of wasted materials or pass that cost on to the buyer. The supplier also plans their production schedules based on confirmed designs. When a design is approved but then revised, the supplier must reschedule production, which might push the delivery date back by 1-2 weeks beyond the time lost to the revision itself. The procurement team has not only lost 1-2 weeks to the approval process—they have lost an additional 1-2 weeks to production queue repositioning. The total timeline impact is 3-4 weeks, not the 1-2 weeks that the procurement team expected.

When planning timelines for custom corporate gift projects, it's essential to account for the full scope of design development, stakeholder alignment, and production preparation. For comprehensive guidance on structuring realistic timelines that accommodate internal approvals, supplier coordination, and production milestones, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to implement parallel approval processes instead of sequential approval processes. Instead of waiting for procurement to approve the design before circulating it to marketing, compliance, and executive stakeholders, the procurement manager should circulate the design to all stakeholders simultaneously as soon as the initial proof is received from the supplier. This requires setting clear expectations with stakeholders about the approval timeline—for example, "Please review and provide feedback within 3 business days"—and establishing a single point of consolidation for all feedback. The procurement manager collects all feedback from all stakeholders, consolidates it into a single revision request, and sends it to the supplier. This approach reduces the number of revision cycles from 3-4 (one per stakeholder) to 1-2 (one consolidated round, potentially one follow-up). The time saved is 2-3 weeks, which is the difference between meeting the delivery deadline and missing it.

The organizational discipline required to implement parallel approvals is often underestimated by procurement teams. In large organizations, stakeholders are busy, and getting them to review a design proof within 3 business days can be challenging. Procurement teams should anticipate these delays and build them into the project timeline from the outset. By adding 2-3 weeks to the initial timeline estimate specifically for "internal stakeholder alignment," procurement teams can avoid the costly surprises that arise when "design approved by procurement" is mistakenly interpreted as "design approved by all stakeholders and production can begin." This small operational improvement—explicitly planning for parallel approvals and communicating realistic timelines to internal stakeholders—can prevent significant timeline slippage and ensure that production begins on schedule.

The supplier's perspective on design approval is fundamentally different from the buyer's perspective. For buyers, design approval is a milestone that signals progress and allows them to move on to the next task. For suppliers, design approval is a gate that must be fully cleared before any production-related commitments can be made. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that "design approved by procurement" means "production started," while suppliers assume that "design approved by procurement" means "awaiting approval from other stakeholders." The gap between these assumptions is 2-4 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for internal stakeholder alignment time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from order placement to final delivery.

The risk of timeline slippage increases significantly when stakeholders request "minor changes" after the initial design approval. A "minor change" from the stakeholder's perspective—such as adjusting the logo size, changing a color shade, or adding a line of text—is not minor from the supplier's perspective. Each change requires a new design proof, a new round of internal approvals, and potentially a new round of material sourcing if the change affects printing specifications. A logo size adjustment might seem trivial, but it requires the supplier to regenerate the entire print file, create a new proof, and wait for approval from all stakeholders again. A color shade adjustment requires the supplier to create a new color swatch, send it for approval, and potentially adjust the printing process. A text addition requires the supplier to reflow the layout, ensure compliance with regulatory requirements, and create a new proof. Each of these "minor changes" adds 3-7 days to the timeline, and if multiple stakeholders request changes sequentially, the cumulative delay can be 2-3 weeks.

The hidden cost of approval delays extends beyond timeline slippage—it affects material procurement and production queue positioning. Suppliers plan their material procurement based on confirmed designs. When a procurement team approves a design but then requests changes after materials have been ordered, the supplier must either absorb the cost of wasted materials or pass that cost on to the buyer. The supplier also plans their production schedules based on confirmed designs. When a design is approved but then revised, the supplier must reschedule production, which might push the delivery date back by 1-2 weeks beyond the time lost to the revision itself. The procurement team has not only lost 1-2 weeks to the approval process—they have lost an additional 1-2 weeks to production queue repositioning. The total timeline impact is 3-4 weeks, not the 1-2 weeks that the procurement team expected.

When planning timelines for custom corporate gift projects, it's essential to account for the full scope of design development, stakeholder alignment, and production preparation. For comprehensive guidance on structuring realistic timelines that accommodate internal approvals, supplier coordination, and production milestones, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to implement parallel approval processes instead of sequential approval processes. Instead of waiting for procurement to approve the design before circulating it to marketing, compliance, and executive stakeholders, the procurement manager should circulate the design to all stakeholders simultaneously as soon as the initial proof is received from the supplier. This requires setting clear expectations with stakeholders about the approval timeline—for example, "Please review and provide feedback within 3 business days"—and establishing a single point of consolidation for all feedback. The procurement manager collects all feedback from all stakeholders, consolidates it into a single revision request, and sends it to the supplier. This approach reduces the number of revision cycles from 3-4 (one per stakeholder) to 1-2 (one consolidated round, potentially one follow-up). The time saved is 2-3 weeks, which is the difference between meeting the delivery deadline and missing it.

The organizational discipline required to implement parallel approvals is often underestimated by procurement teams. In large organizations, stakeholders are busy, and getting them to review a design proof within 3 business days can be challenging. Procurement teams should anticipate these delays and build them into the project timeline from the outset. By adding 2-3 weeks to the initial timeline estimate specifically for "internal stakeholder alignment," procurement teams can avoid the costly surprises that arise when "design approved by procurement" is mistakenly interpreted as "design approved by all stakeholders and production can begin." This small operational improvement—explicitly planning for parallel approvals and communicating realistic timelines to internal stakeholders—can prevent significant timeline slippage and ensure that production begins on schedule.

The supplier's perspective on design approval is fundamentally different from the buyer's perspective. For buyers, design approval is a milestone that signals progress and allows them to move on to the next task. For suppliers, design approval is a gate that must be fully cleared before any production-related commitments can be made. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that "design approved by procurement" means "production started," while suppliers assume that "design approved by procurement" means "awaiting approval from other stakeholders." The gap between these assumptions is 2-4 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for internal stakeholder alignment time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from order placement to final delivery.

The timeline impact of sequential approvals is rarely visible in the initial project plan. When a procurement manager places an order for custom corporate gift boxes and receives a design proof from the supplier, they typically allow 3-5 business days for internal review and approval. This timeline assumes that the design will be reviewed and approved by all relevant stakeholders within that window. In reality, the approval process is sequential, not parallel. The procurement manager reviews the design first and provides their approval to the supplier. The supplier then asks, "Has this been approved by your marketing team?" The procurement manager forwards the design to marketing, who reviews it 2-3 days later and requests a color adjustment. The supplier makes the adjustment and sends a revised proof. The procurement manager forwards it to marketing again, who approves it 1-2 days later. The supplier then asks, "Has this been approved by your compliance team?" The procurement manager forwards the design to compliance, who reviews it 3-4 days later and requests additional regulatory text. The supplier makes the adjustment and sends another revised proof. This cycle continues until all stakeholders have approved the design. The total time from "procurement approval" to "all stakeholders approved" is 2-4 weeks, not the 3-5 days that the procurement manager originally budgeted.

The compounding effect occurs when the procurement manager uses the supplier's "production lead time" as the basis for their internal delivery timeline. A procurement manager places an order on February 1st, receives a design proof on February 5th, approves it on February 8th, and calculates a delivery date of April 5th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for April 15th. The manager assumes production begins on February 8th, the day they approved the design. In reality, production begins on March 1st, after the marketing team requests a logo adjustment (February 12-15), the compliance team requests regulatory text (February 19-22), and the executive sponsor requests a messaging change (February 26-28). The actual delivery date is April 26th, not April 5th. The procurement manager has underestimated the timeline by 3 weeks, and the corporate event is now at risk.

The approval workflow involves multiple steps that are invisible to the supplier but critical to the timeline. When the procurement manager receives the initial design proof, they review it against the purchase order specifications and provide their approval. At this point, the procurement manager believes the design is final and production can begin. The supplier, however, knows from experience that the design will need to be reviewed by other stakeholders. The supplier asks, "Has this been approved by your marketing and compliance teams?" If the procurement manager has not yet circulated the design to these teams, the supplier must wait. The supplier cannot order materials until the design is fully approved, because any changes to the design after materials are ordered will result in waste and additional costs. The supplier also cannot schedule production capacity until the design is approved, because production schedules are planned weeks in advance and any changes to the design will require rescheduling. The supplier is not being difficult—they are protecting both parties from the costly consequences of starting production before the design is truly final.

The timeline impact of sequential approvals is rarely visible in the initial project plan. When a procurement manager places an order for custom corporate gift boxes and receives a design proof from the supplier, they typically allow 3-5 business days for internal review and approval. This timeline assumes that the design will be reviewed and approved by all relevant stakeholders within that window. In reality, the approval process is sequential, not parallel. The procurement manager reviews the design first and provides their approval to the supplier. The supplier then asks, "Has this been approved by your marketing team?" The procurement manager forwards the design to marketing, who reviews it 2-3 days later and requests a color adjustment. The supplier makes the adjustment and sends a revised proof. The procurement manager forwards it to marketing again, who approves it 1-2 days later. The supplier then asks, "Has this been approved by your compliance team?" The procurement manager forwards the design to compliance, who reviews it 3-4 days later and requests additional regulatory text. The supplier makes the adjustment and sends another revised proof. This cycle continues until all stakeholders have approved the design. The total time from "procurement approval" to "all stakeholders approved" is 2-4 weeks, not the 3-5 days that the procurement manager originally budgeted.

The compounding effect occurs when the procurement manager uses the supplier's "production lead time" as the basis for their internal delivery timeline. A procurement manager places an order on February 1st, receives a design proof on February 5th, approves it on February 8th, and calculates a delivery date of April 5th (8 weeks production + 1 week shipping). The manager communicates this timeline to internal stakeholders, who plan their corporate event for April 15th. The manager assumes production begins on February 8th, the day they approved the design. In reality, production begins on March 1st, after the marketing team requests a logo adjustment (February 12-15), the compliance team requests regulatory text (February 19-22), and the executive sponsor requests a messaging change (February 26-28). The actual delivery date is April 26th, not April 5th. The procurement manager has underestimated the timeline by 3 weeks, and the corporate event is now at risk.

The approval workflow involves multiple steps that are invisible to the supplier but critical to the timeline. When the procurement manager receives the initial design proof, they review it against the purchase order specifications and provide their approval. At this point, the procurement manager believes the design is final and production can begin. The supplier, however, knows from experience that the design will need to be reviewed by other stakeholders. The supplier asks, "Has this been approved by your marketing and compliance teams?" If the procurement manager has not yet circulated the design to these teams, the supplier must wait. The supplier cannot order materials until the design is fully approved, because any changes to the design after materials are ordered will result in waste and additional costs. The supplier also cannot schedule production capacity until the design is approved, because production schedules are planned weeks in advance and any changes to the design will require rescheduling. The supplier is not being difficult—they are protecting both parties from the costly consequences of starting production before the design is truly final.

The risk of timeline slippage increases significantly when stakeholders request "minor changes" after the initial design approval. A "minor change" from the stakeholder's perspective—such as adjusting the logo size, changing a color shade, or adding a line of text—is not minor from the supplier's perspective. Each change requires a new design proof, a new round of internal approvals, and potentially a new round of material sourcing if the change affects printing specifications. A logo size adjustment might seem trivial, but it requires the supplier to regenerate the entire print file, create a new proof, and wait for approval from all stakeholders again. A color shade adjustment requires the supplier to create a new color swatch, send it for approval, and potentially adjust the printing process. A text addition requires the supplier to reflow the layout, ensure compliance with regulatory requirements, and create a new proof. Each of these "minor changes" adds 3-7 days to the timeline, and if multiple stakeholders request changes sequentially, the cumulative delay can be 2-3 weeks.

The hidden cost of approval delays extends beyond timeline slippage—it affects material procurement and production queue positioning. Suppliers plan their material procurement based on confirmed designs. When a procurement team approves a design but then requests changes after materials have been ordered, the supplier must either absorb the cost of wasted materials or pass that cost on to the buyer. The supplier also plans their production schedules based on confirmed designs. When a design is approved but then revised, the supplier must reschedule production, which might push the delivery date back by 1-2 weeks beyond the time lost to the revision itself. The procurement team has not only lost 1-2 weeks to the approval process—they have lost an additional 1-2 weeks to production queue repositioning. The total timeline impact is 3-4 weeks, not the 1-2 weeks that the procurement team expected.

When planning timelines for custom corporate gift projects, it's essential to account for the full scope of design development, stakeholder alignment, and production preparation. For comprehensive guidance on structuring realistic timelines that accommodate internal approvals, supplier coordination, and production milestones, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to implement parallel approval processes instead of sequential approval processes. Instead of waiting for procurement to approve the design before circulating it to marketing, compliance, and executive stakeholders, the procurement manager should circulate the design to all stakeholders simultaneously as soon as the initial proof is received from the supplier. This requires setting clear expectations with stakeholders about the approval timeline—for example, "Please review and provide feedback within 3 business days"—and establishing a single point of consolidation for all feedback. The procurement manager collects all feedback from all stakeholders, consolidates it into a single revision request, and sends it to the supplier. This approach reduces the number of revision cycles from 3-4 (one per stakeholder) to 1-2 (one consolidated round, potentially one follow-up). The time saved is 2-3 weeks, which is the difference between meeting the delivery deadline and missing it.

The organizational discipline required to implement parallel approvals is often underestimated by procurement teams. In large organizations, stakeholders are busy, and getting them to review a design proof within 3 business days can be challenging. Procurement teams should anticipate these delays and build them into the project timeline from the outset. By adding 2-3 weeks to the initial timeline estimate specifically for "internal stakeholder alignment," procurement teams can avoid the costly surprises that arise when "design approved by procurement" is mistakenly interpreted as "design approved by all stakeholders and production can begin." This small operational improvement—explicitly planning for parallel approvals and communicating realistic timelines to internal stakeholders—can prevent significant timeline slippage and ensure that production begins on schedule.

The supplier's perspective on design approval is fundamentally different from the buyer's perspective. For buyers, design approval is a milestone that signals progress and allows them to move on to the next task. For suppliers, design approval is a gate that must be fully cleared before any production-related commitments can be made. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that "design approved by procurement" means "production started," while suppliers assume that "design approved by procurement" means "awaiting approval from other stakeholders." The gap between these assumptions is 2-4 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for internal stakeholder alignment time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from order placement to final delivery.

The risk of timeline slippage increases significantly when stakeholders request "minor changes" after the initial design approval. A "minor change" from the stakeholder's perspective—such as adjusting the logo size, changing a color shade, or adding a line of text—is not minor from the supplier's perspective. Each change requires a new design proof, a new round of internal approvals, and potentially a new round of material sourcing if the change affects printing specifications. A logo size adjustment might seem trivial, but it requires the supplier to regenerate the entire print file, create a new proof, and wait for approval from all stakeholders again. A color shade adjustment requires the supplier to create a new color swatch, send it for approval, and potentially adjust the printing process. A text addition requires the supplier to reflow the layout, ensure compliance with regulatory requirements, and create a new proof. Each of these "minor changes" adds 3-7 days to the timeline, and if multiple stakeholders request changes sequentially, the cumulative delay can be 2-3 weeks.

The hidden cost of approval delays extends beyond timeline slippage—it affects material procurement and production queue positioning. Suppliers plan their material procurement based on confirmed designs. When a procurement team approves a design but then requests changes after materials have been ordered, the supplier must either absorb the cost of wasted materials or pass that cost on to the buyer. The supplier also plans their production schedules based on confirmed designs. When a design is approved but then revised, the supplier must reschedule production, which might push the delivery date back by 1-2 weeks beyond the time lost to the revision itself. The procurement team has not only lost 1-2 weeks to the approval process—they have lost an additional 1-2 weeks to production queue repositioning. The total timeline impact is 3-4 weeks, not the 1-2 weeks that the procurement team expected.

When planning timelines for custom corporate gift projects, it's essential to account for the full scope of design development, stakeholder alignment, and production preparation. For comprehensive guidance on structuring realistic timelines that accommodate internal approvals, supplier coordination, and production milestones, refer to our [detailed guide on customization planning](/resources/customization-process-guide), which addresses the complete journey from initial concept through final delivery.

The practical solution for procurement teams is to implement parallel approval processes instead of sequential approval processes. Instead of waiting for procurement to approve the design before circulating it to marketing, compliance, and executive stakeholders, the procurement manager should circulate the design to all stakeholders simultaneously as soon as the initial proof is received from the supplier. This requires setting clear expectations with stakeholders about the approval timeline—for example, "Please review and provide feedback within 3 business days"—and establishing a single point of consolidation for all feedback. The procurement manager collects all feedback from all stakeholders, consolidates it into a single revision request, and sends it to the supplier. This approach reduces the number of revision cycles from 3-4 (one per stakeholder) to 1-2 (one consolidated round, potentially one follow-up). The time saved is 2-3 weeks, which is the difference between meeting the delivery deadline and missing it.

The organizational discipline required to implement parallel approvals is often underestimated by procurement teams. In large organizations, stakeholders are busy, and getting them to review a design proof within 3 business days can be challenging. Procurement teams should anticipate these delays and build them into the project timeline from the outset. By adding 2-3 weeks to the initial timeline estimate specifically for "internal stakeholder alignment," procurement teams can avoid the costly surprises that arise when "design approved by procurement" is mistakenly interpreted as "design approved by all stakeholders and production can begin." This small operational improvement—explicitly planning for parallel approvals and communicating realistic timelines to internal stakeholders—can prevent significant timeline slippage and ensure that production begins on schedule.

The supplier's perspective on design approval is fundamentally different from the buyer's perspective. For buyers, design approval is a milestone that signals progress and allows them to move on to the next task. For suppliers, design approval is a gate that must be fully cleared before any production-related commitments can be made. The disconnect between these perspectives is where timeline misjudgments occur. Buyers assume that "design approved by procurement" means "production started," while suppliers assume that "design approved by procurement" means "awaiting approval from other stakeholders." The gap between these assumptions is 2-4 weeks, and it's rarely communicated clearly in initial project plans. By understanding the supplier's perspective and explicitly accounting for internal stakeholder alignment time, procurement teams can bridge this gap and plan realistic timelines that account for the full door-to-door journey from order placement to final delivery.

You May Also Like

Rigid Box vs. Corrugated Mailer: Which Material Suits Your Premium Corporate Gifts?

A deep dive into the structural integrity, cost implications, and unboxing experience of rigid boxes versus corrugated mailers for high-end corporate gifting.

Foil Stamping vs. UV Spot: Elevating Your Brand Logo on Custom Gift Boxes

A technical comparison of hot foil stamping and UV spot varnish, analyzing visual impact, durability, and production costs for branded corporate packaging.