Back to BlogLead Time

Why Each 'Minor Tweak' to Your Corporate Gift Box Sample Adds Weeks, Not Days

2026-01-11

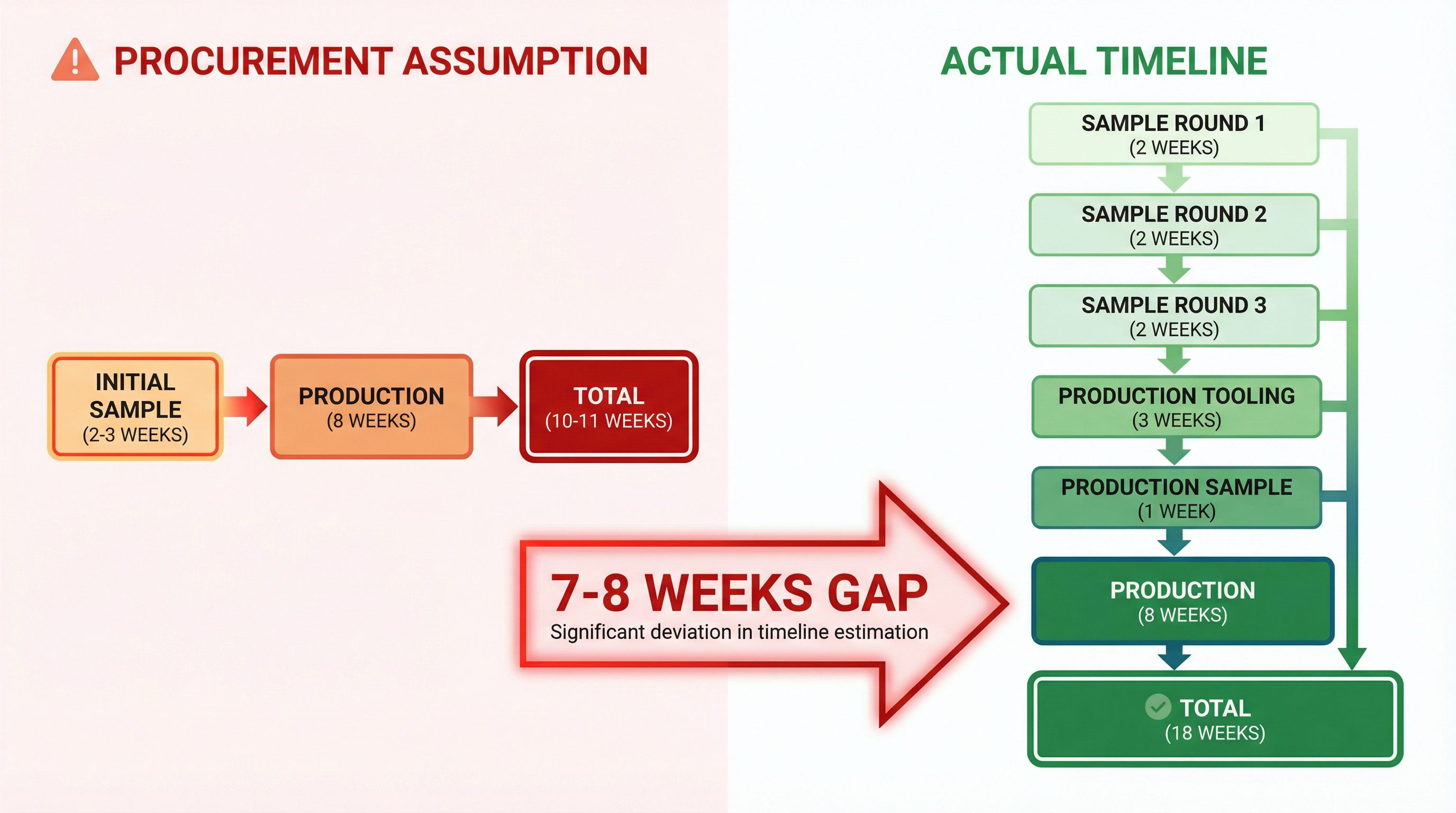

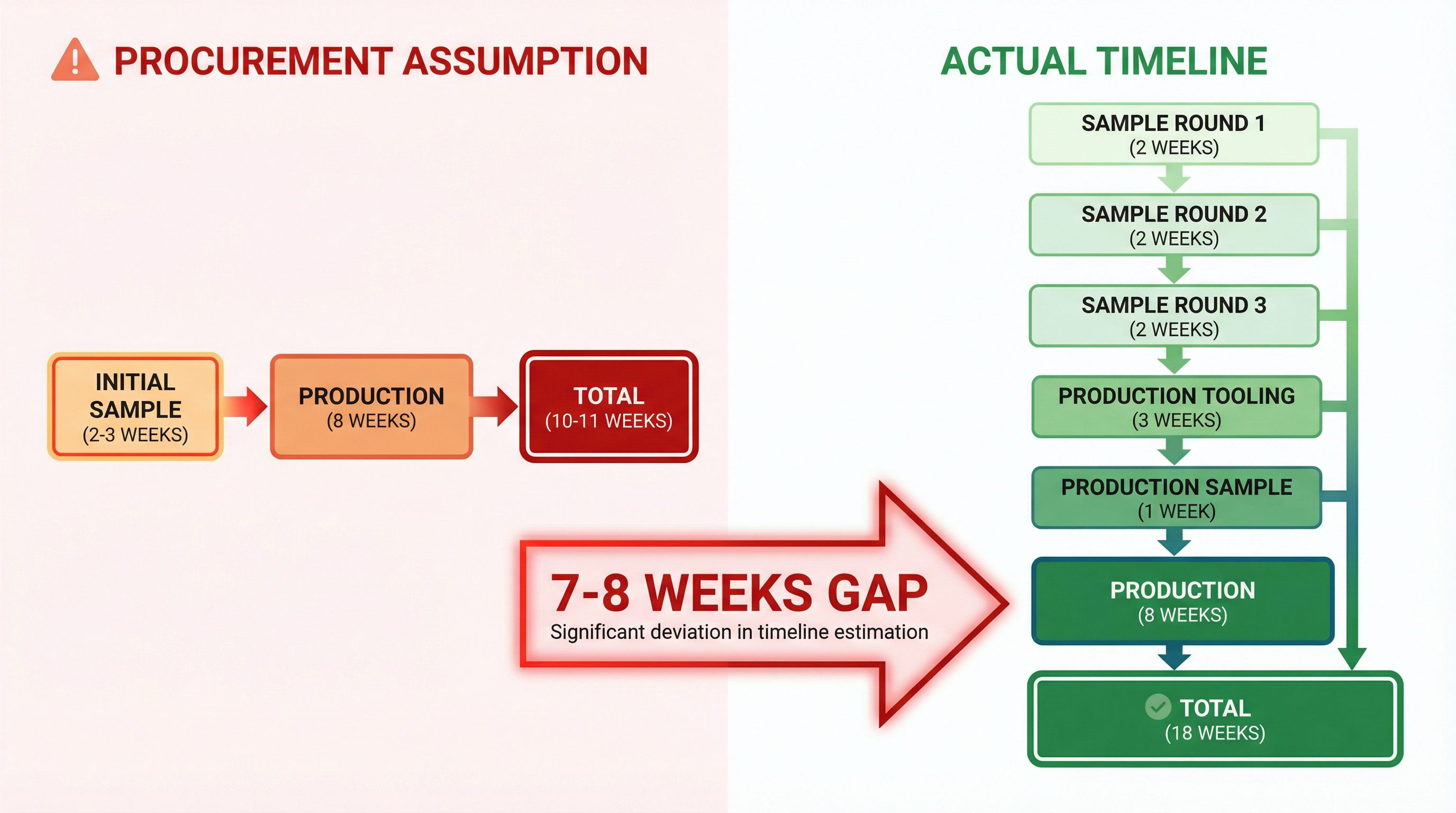

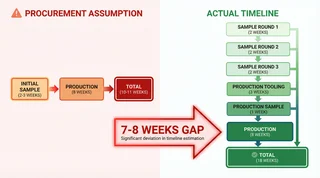

In practice, this is often where lead time decisions start to be misjudged. A procurement manager receives an initial sample of a custom corporate gift box in two weeks and is impressed with the speed. They provide feedback—"Can we adjust the logo size by 15%? And make the ribbon slightly darker?"—and expect the revised sample in another two weeks. When the manager places the production order after three sample rounds, they budget for 8 weeks of production time plus the 6 weeks spent on sampling, expecting delivery in 14 weeks total. The actual delivery arrives in week 22. The procurement manager is confused: the supplier produced the sample quickly, so why is the supplier now so slow? The answer reveals a fundamental misunderstanding about how manufacturing works. Sampling and production are not two versions of the same process—they are entirely different operational systems with different equipment, labor, quality standards, and timelines.

The speed of the initial sample creates a false baseline for all subsequent expectations. When a factory produces a first sample in two weeks, they are using manual processes, flexible tooling, and skilled technicians who can quickly adjust designs. A skilled technician can modify a printing screen, adjust an embossing template, or change a ribbon color in hours. The tooling for sampling is temporary—a 3D-printed mold, a hand-cut stencil, a manually adjusted die-cutting template. These tools are inexpensive and fast to produce, but they are not suitable for production scale. When the procurement team requests a "minor tweak" to the logo size, they assume the technician will simply adjust the existing tooling and produce a new sample. This assumption is correct for the first sample. It is incorrect for the second, third, and fourth samples.

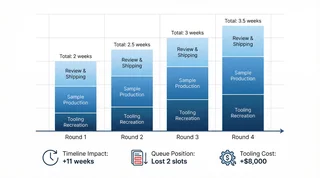

Each sample iteration requires the factory to return to the beginning of the sampling process. The technician cannot simply "adjust" the existing tooling—they must create new tooling from scratch. A 15% logo size change requires a new printing screen, a new embossing die, and a new quality reference sample. The printing screen must be re-exposed with the new logo artwork, which takes 1-2 days. The embossing die must be re-machined or re-printed, which takes 2-3 days. The quality reference sample must be produced and photographed for the client's approval, which takes 1 day. The total time for a "minor tweak" is 4-6 days of tooling work plus 2-3 days of sample production plus 3-5 days of international shipping plus 2-3 days of client review. The "minor tweak" has added 11-17 days to the timeline, not the 2-3 days the procurement team expected.

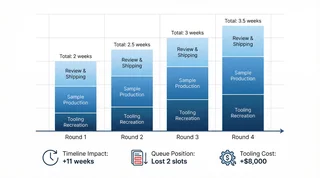

The cumulative effect of multiple sample rounds is where the timeline truly diverges from expectations. A procurement team that budgets for "2-3 weeks of sampling" is assuming a single sample round. In reality, most custom corporate gift box projects require 2-4 sample rounds before the design is finalized. Each round adds 2-3 weeks to the timeline. The first sample addresses the basic design concept. The second sample addresses color accuracy and material texture. The third sample addresses printing quality and assembly details. The fourth sample addresses final packaging and presentation. By the time the design is approved, 8-12 weeks have passed, not the 2-3 weeks originally budgeted. The procurement team is now 6-9 weeks behind their internal schedule, and production has not yet started.

Each sample iteration requires the factory to return to the beginning of the sampling process. The technician cannot simply "adjust" the existing tooling—they must create new tooling from scratch. A 15% logo size change requires a new printing screen, a new embossing die, and a new quality reference sample. The printing screen must be re-exposed with the new logo artwork, which takes 1-2 days. The embossing die must be re-machined or re-printed, which takes 2-3 days. The quality reference sample must be produced and photographed for the client's approval, which takes 1 day. The total time for a "minor tweak" is 4-6 days of tooling work plus 2-3 days of sample production plus 3-5 days of international shipping plus 2-3 days of client review. The "minor tweak" has added 11-17 days to the timeline, not the 2-3 days the procurement team expected.

The cumulative effect of multiple sample rounds is where the timeline truly diverges from expectations. A procurement team that budgets for "2-3 weeks of sampling" is assuming a single sample round. In reality, most custom corporate gift box projects require 2-4 sample rounds before the design is finalized. Each round adds 2-3 weeks to the timeline. The first sample addresses the basic design concept. The second sample addresses color accuracy and material texture. The third sample addresses printing quality and assembly details. The fourth sample addresses final packaging and presentation. By the time the design is approved, 8-12 weeks have passed, not the 2-3 weeks originally budgeted. The procurement team is now 6-9 weeks behind their internal schedule, and production has not yet started.

The transition from sampling tooling to production tooling is invisible to the procurement team but critical to the timeline. Once the design is approved, the factory cannot simply scale up the sampling process to produce 5,000 units. The temporary tooling used for sampling—3D-printed molds, hand-cut stencils, manually adjusted dies—is not durable enough for production scale. The factory must order permanent production tooling: steel molds for injection molding, precision-machined printing screens, automated die-cutting templates. These tools are expensive and require precision engineering, often taking 2-4 weeks to fabricate. If the design changes after the production tooling is ordered, the tooling must be scrapped and a new set ordered, adding another 2-4 weeks to the timeline. This is why factories insist on a "design freeze" date—after that date, design changes are extremely expensive and time-consuming.

The hidden cost of sample iterations is not just time—it is production queue positioning. Factories plan their production schedules weeks in advance. When a procurement team places an order, the factory allocates a production slot based on the expected start date. If the sampling phase extends from 3 weeks to 12 weeks, the original production slot is lost. The factory has filled that slot with another client's order. The procurement team's order must now wait for the next available slot, which might be 2-4 weeks later. The extended sampling phase has not only delayed the start of production—it has pushed the entire project further back in the factory's queue. The procurement team is now 8-13 weeks behind their original schedule, and they have not yet received a single production unit.

The misjudgment becomes compounded when procurement teams treat each sample round as independent rather than cumulative. A procurement manager might think: "We've already spent 6 weeks on sampling, so we're only 2 weeks away from production." This is incorrect. The factory is not 2 weeks away from production—the factory is 2 weeks away from the next sample round, which will be followed by another 2-3 weeks of client review, followed by another 2 weeks of sample production, followed by production tooling fabrication, followed by production queue positioning. The procurement team is not 2 weeks away from production—they are 8-12 weeks away from production. The cumulative effect of sample iterations is not additive—it is multiplicative.

> Understanding the distinction between sampling time and total pre-production time is essential when considering the full scope of factors that affect project timelines for corporate gift programs. For comprehensive guidance on planning realistic timelines from order placement through final delivery, refer to our [lead time guide for corporate gift boxes](/resources/leadtime-pillar), which addresses the full spectrum of factors affecting project duration from initial order through final distribution.

The factory's perspective on sample iterations is fundamentally different from the procurement team's perspective. The procurement team sees each sample round as a minor adjustment—a small tweak to get the design exactly right. The factory sees each sample round as a complete restart of the sampling process—new tooling, new materials, new quality references, new production planning. The procurement team sees sampling as a 2-3 week phase that precedes production. The factory sees sampling as a 6-12 week phase that includes multiple tooling cycles, client review periods, and production planning adjustments. The procurement team sees "minor tweaks" as low-cost, low-time adjustments. The factory sees "minor tweaks" as high-cost, high-time restarts that push the entire project further back in the production queue.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 6-10 weeks. A project that was expected to take 14 weeks (3 weeks sampling + 8 weeks production + 3 weeks shipping) actually takes 22-24 weeks (12 weeks sampling + 3 weeks tooling transition + 8 weeks production + 3 weeks shipping). The procurement team has missed their internal deadline by 8-10 weeks, and they are now scrambling to explain the delay to their stakeholders. The factory has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 12 weeks of pre-production time required to finalize the design and fabricate production tooling.

The shipping and logistics phase represents a significant but often overlooked component of the total timeline, and failure to account for this phase can result in missed deadlines, emergency logistics costs, and stakeholder frustration. By explicitly planning for the complete sampling cycle—including multiple revision rounds, tooling transitions, and production queue positioning—and by requesting transparent door-to-door timelines from factories, procurement teams can avoid the costly surprises that arise when "production complete" is mistakenly interpreted as "goods ready to distribute."

The transition from sampling tooling to production tooling is invisible to the procurement team but critical to the timeline. Once the design is approved, the factory cannot simply scale up the sampling process to produce 5,000 units. The temporary tooling used for sampling—3D-printed molds, hand-cut stencils, manually adjusted dies—is not durable enough for production scale. The factory must order permanent production tooling: steel molds for injection molding, precision-machined printing screens, automated die-cutting templates. These tools are expensive and require precision engineering, often taking 2-4 weeks to fabricate. If the design changes after the production tooling is ordered, the tooling must be scrapped and a new set ordered, adding another 2-4 weeks to the timeline. This is why factories insist on a "design freeze" date—after that date, design changes are extremely expensive and time-consuming.

The hidden cost of sample iterations is not just time—it is production queue positioning. Factories plan their production schedules weeks in advance. When a procurement team places an order, the factory allocates a production slot based on the expected start date. If the sampling phase extends from 3 weeks to 12 weeks, the original production slot is lost. The factory has filled that slot with another client's order. The procurement team's order must now wait for the next available slot, which might be 2-4 weeks later. The extended sampling phase has not only delayed the start of production—it has pushed the entire project further back in the factory's queue. The procurement team is now 8-13 weeks behind their original schedule, and they have not yet received a single production unit.

The misjudgment becomes compounded when procurement teams treat each sample round as independent rather than cumulative. A procurement manager might think: "We've already spent 6 weeks on sampling, so we're only 2 weeks away from production." This is incorrect. The factory is not 2 weeks away from production—the factory is 2 weeks away from the next sample round, which will be followed by another 2-3 weeks of client review, followed by another 2 weeks of sample production, followed by production tooling fabrication, followed by production queue positioning. The procurement team is not 2 weeks away from production—they are 8-12 weeks away from production. The cumulative effect of sample iterations is not additive—it is multiplicative.

> Understanding the distinction between sampling time and total pre-production time is essential when considering the full scope of factors that affect project timelines for corporate gift programs. For comprehensive guidance on planning realistic timelines from order placement through final delivery, refer to our [lead time guide for corporate gift boxes](/resources/leadtime-pillar), which addresses the full spectrum of factors affecting project duration from initial order through final distribution.

The factory's perspective on sample iterations is fundamentally different from the procurement team's perspective. The procurement team sees each sample round as a minor adjustment—a small tweak to get the design exactly right. The factory sees each sample round as a complete restart of the sampling process—new tooling, new materials, new quality references, new production planning. The procurement team sees sampling as a 2-3 week phase that precedes production. The factory sees sampling as a 6-12 week phase that includes multiple tooling cycles, client review periods, and production planning adjustments. The procurement team sees "minor tweaks" as low-cost, low-time adjustments. The factory sees "minor tweaks" as high-cost, high-time restarts that push the entire project further back in the production queue.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 6-10 weeks. A project that was expected to take 14 weeks (3 weeks sampling + 8 weeks production + 3 weeks shipping) actually takes 22-24 weeks (12 weeks sampling + 3 weeks tooling transition + 8 weeks production + 3 weeks shipping). The procurement team has missed their internal deadline by 8-10 weeks, and they are now scrambling to explain the delay to their stakeholders. The factory has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 12 weeks of pre-production time required to finalize the design and fabricate production tooling.

The shipping and logistics phase represents a significant but often overlooked component of the total timeline, and failure to account for this phase can result in missed deadlines, emergency logistics costs, and stakeholder frustration. By explicitly planning for the complete sampling cycle—including multiple revision rounds, tooling transitions, and production queue positioning—and by requesting transparent door-to-door timelines from factories, procurement teams can avoid the costly surprises that arise when "production complete" is mistakenly interpreted as "goods ready to distribute."

Each sample iteration requires the factory to return to the beginning of the sampling process. The technician cannot simply "adjust" the existing tooling—they must create new tooling from scratch. A 15% logo size change requires a new printing screen, a new embossing die, and a new quality reference sample. The printing screen must be re-exposed with the new logo artwork, which takes 1-2 days. The embossing die must be re-machined or re-printed, which takes 2-3 days. The quality reference sample must be produced and photographed for the client's approval, which takes 1 day. The total time for a "minor tweak" is 4-6 days of tooling work plus 2-3 days of sample production plus 3-5 days of international shipping plus 2-3 days of client review. The "minor tweak" has added 11-17 days to the timeline, not the 2-3 days the procurement team expected.

The cumulative effect of multiple sample rounds is where the timeline truly diverges from expectations. A procurement team that budgets for "2-3 weeks of sampling" is assuming a single sample round. In reality, most custom corporate gift box projects require 2-4 sample rounds before the design is finalized. Each round adds 2-3 weeks to the timeline. The first sample addresses the basic design concept. The second sample addresses color accuracy and material texture. The third sample addresses printing quality and assembly details. The fourth sample addresses final packaging and presentation. By the time the design is approved, 8-12 weeks have passed, not the 2-3 weeks originally budgeted. The procurement team is now 6-9 weeks behind their internal schedule, and production has not yet started.

Each sample iteration requires the factory to return to the beginning of the sampling process. The technician cannot simply "adjust" the existing tooling—they must create new tooling from scratch. A 15% logo size change requires a new printing screen, a new embossing die, and a new quality reference sample. The printing screen must be re-exposed with the new logo artwork, which takes 1-2 days. The embossing die must be re-machined or re-printed, which takes 2-3 days. The quality reference sample must be produced and photographed for the client's approval, which takes 1 day. The total time for a "minor tweak" is 4-6 days of tooling work plus 2-3 days of sample production plus 3-5 days of international shipping plus 2-3 days of client review. The "minor tweak" has added 11-17 days to the timeline, not the 2-3 days the procurement team expected.

The cumulative effect of multiple sample rounds is where the timeline truly diverges from expectations. A procurement team that budgets for "2-3 weeks of sampling" is assuming a single sample round. In reality, most custom corporate gift box projects require 2-4 sample rounds before the design is finalized. Each round adds 2-3 weeks to the timeline. The first sample addresses the basic design concept. The second sample addresses color accuracy and material texture. The third sample addresses printing quality and assembly details. The fourth sample addresses final packaging and presentation. By the time the design is approved, 8-12 weeks have passed, not the 2-3 weeks originally budgeted. The procurement team is now 6-9 weeks behind their internal schedule, and production has not yet started.

The transition from sampling tooling to production tooling is invisible to the procurement team but critical to the timeline. Once the design is approved, the factory cannot simply scale up the sampling process to produce 5,000 units. The temporary tooling used for sampling—3D-printed molds, hand-cut stencils, manually adjusted dies—is not durable enough for production scale. The factory must order permanent production tooling: steel molds for injection molding, precision-machined printing screens, automated die-cutting templates. These tools are expensive and require precision engineering, often taking 2-4 weeks to fabricate. If the design changes after the production tooling is ordered, the tooling must be scrapped and a new set ordered, adding another 2-4 weeks to the timeline. This is why factories insist on a "design freeze" date—after that date, design changes are extremely expensive and time-consuming.

The hidden cost of sample iterations is not just time—it is production queue positioning. Factories plan their production schedules weeks in advance. When a procurement team places an order, the factory allocates a production slot based on the expected start date. If the sampling phase extends from 3 weeks to 12 weeks, the original production slot is lost. The factory has filled that slot with another client's order. The procurement team's order must now wait for the next available slot, which might be 2-4 weeks later. The extended sampling phase has not only delayed the start of production—it has pushed the entire project further back in the factory's queue. The procurement team is now 8-13 weeks behind their original schedule, and they have not yet received a single production unit.

The misjudgment becomes compounded when procurement teams treat each sample round as independent rather than cumulative. A procurement manager might think: "We've already spent 6 weeks on sampling, so we're only 2 weeks away from production." This is incorrect. The factory is not 2 weeks away from production—the factory is 2 weeks away from the next sample round, which will be followed by another 2-3 weeks of client review, followed by another 2 weeks of sample production, followed by production tooling fabrication, followed by production queue positioning. The procurement team is not 2 weeks away from production—they are 8-12 weeks away from production. The cumulative effect of sample iterations is not additive—it is multiplicative.

> Understanding the distinction between sampling time and total pre-production time is essential when considering the full scope of factors that affect project timelines for corporate gift programs. For comprehensive guidance on planning realistic timelines from order placement through final delivery, refer to our [lead time guide for corporate gift boxes](/resources/leadtime-pillar), which addresses the full spectrum of factors affecting project duration from initial order through final distribution.

The factory's perspective on sample iterations is fundamentally different from the procurement team's perspective. The procurement team sees each sample round as a minor adjustment—a small tweak to get the design exactly right. The factory sees each sample round as a complete restart of the sampling process—new tooling, new materials, new quality references, new production planning. The procurement team sees sampling as a 2-3 week phase that precedes production. The factory sees sampling as a 6-12 week phase that includes multiple tooling cycles, client review periods, and production planning adjustments. The procurement team sees "minor tweaks" as low-cost, low-time adjustments. The factory sees "minor tweaks" as high-cost, high-time restarts that push the entire project further back in the production queue.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 6-10 weeks. A project that was expected to take 14 weeks (3 weeks sampling + 8 weeks production + 3 weeks shipping) actually takes 22-24 weeks (12 weeks sampling + 3 weeks tooling transition + 8 weeks production + 3 weeks shipping). The procurement team has missed their internal deadline by 8-10 weeks, and they are now scrambling to explain the delay to their stakeholders. The factory has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 12 weeks of pre-production time required to finalize the design and fabricate production tooling.

The shipping and logistics phase represents a significant but often overlooked component of the total timeline, and failure to account for this phase can result in missed deadlines, emergency logistics costs, and stakeholder frustration. By explicitly planning for the complete sampling cycle—including multiple revision rounds, tooling transitions, and production queue positioning—and by requesting transparent door-to-door timelines from factories, procurement teams can avoid the costly surprises that arise when "production complete" is mistakenly interpreted as "goods ready to distribute."

The transition from sampling tooling to production tooling is invisible to the procurement team but critical to the timeline. Once the design is approved, the factory cannot simply scale up the sampling process to produce 5,000 units. The temporary tooling used for sampling—3D-printed molds, hand-cut stencils, manually adjusted dies—is not durable enough for production scale. The factory must order permanent production tooling: steel molds for injection molding, precision-machined printing screens, automated die-cutting templates. These tools are expensive and require precision engineering, often taking 2-4 weeks to fabricate. If the design changes after the production tooling is ordered, the tooling must be scrapped and a new set ordered, adding another 2-4 weeks to the timeline. This is why factories insist on a "design freeze" date—after that date, design changes are extremely expensive and time-consuming.

The hidden cost of sample iterations is not just time—it is production queue positioning. Factories plan their production schedules weeks in advance. When a procurement team places an order, the factory allocates a production slot based on the expected start date. If the sampling phase extends from 3 weeks to 12 weeks, the original production slot is lost. The factory has filled that slot with another client's order. The procurement team's order must now wait for the next available slot, which might be 2-4 weeks later. The extended sampling phase has not only delayed the start of production—it has pushed the entire project further back in the factory's queue. The procurement team is now 8-13 weeks behind their original schedule, and they have not yet received a single production unit.

The misjudgment becomes compounded when procurement teams treat each sample round as independent rather than cumulative. A procurement manager might think: "We've already spent 6 weeks on sampling, so we're only 2 weeks away from production." This is incorrect. The factory is not 2 weeks away from production—the factory is 2 weeks away from the next sample round, which will be followed by another 2-3 weeks of client review, followed by another 2 weeks of sample production, followed by production tooling fabrication, followed by production queue positioning. The procurement team is not 2 weeks away from production—they are 8-12 weeks away from production. The cumulative effect of sample iterations is not additive—it is multiplicative.

> Understanding the distinction between sampling time and total pre-production time is essential when considering the full scope of factors that affect project timelines for corporate gift programs. For comprehensive guidance on planning realistic timelines from order placement through final delivery, refer to our [lead time guide for corporate gift boxes](/resources/leadtime-pillar), which addresses the full spectrum of factors affecting project duration from initial order through final distribution.

The factory's perspective on sample iterations is fundamentally different from the procurement team's perspective. The procurement team sees each sample round as a minor adjustment—a small tweak to get the design exactly right. The factory sees each sample round as a complete restart of the sampling process—new tooling, new materials, new quality references, new production planning. The procurement team sees sampling as a 2-3 week phase that precedes production. The factory sees sampling as a 6-12 week phase that includes multiple tooling cycles, client review periods, and production planning adjustments. The procurement team sees "minor tweaks" as low-cost, low-time adjustments. The factory sees "minor tweaks" as high-cost, high-time restarts that push the entire project further back in the production queue.

The practical consequence of this misjudgment is that procurement teams consistently underestimate total lead time by 6-10 weeks. A project that was expected to take 14 weeks (3 weeks sampling + 8 weeks production + 3 weeks shipping) actually takes 22-24 weeks (12 weeks sampling + 3 weeks tooling transition + 8 weeks production + 3 weeks shipping). The procurement team has missed their internal deadline by 8-10 weeks, and they are now scrambling to explain the delay to their stakeholders. The factory has delivered exactly what was promised—8 weeks of production time—but the procurement team did not account for the 12 weeks of pre-production time required to finalize the design and fabricate production tooling.

The shipping and logistics phase represents a significant but often overlooked component of the total timeline, and failure to account for this phase can result in missed deadlines, emergency logistics costs, and stakeholder frustration. By explicitly planning for the complete sampling cycle—including multiple revision rounds, tooling transitions, and production queue positioning—and by requesting transparent door-to-door timelines from factories, procurement teams can avoid the costly surprises that arise when "production complete" is mistakenly interpreted as "goods ready to distribute."

You May Also Like

Rigid Box vs. Corrugated Mailer: Which Material Suits Your Premium Corporate Gifts?

A deep dive into the structural integrity, cost implications, and unboxing experience of rigid boxes versus corrugated mailers for high-end corporate gifting.

Foil Stamping vs. UV Spot: Elevating Your Brand Logo on Custom Gift Boxes

A technical comparison of hot foil stamping and UV spot varnish, analyzing visual impact, durability, and production costs for branded corporate packaging.