Back to BlogLEAD TIME

Why 'Production Complete' Doesn't Mean Your Corporate Gift Boxes Are Ready to Distribute

2026-01-10

When a procurement team receives confirmation from the factory that production has been completed, the immediate assumption is that the project timeline is nearly finished. The boxes have been manufactured, quality checks have been performed, and the goods are ready for distribution. From a procurement planning perspective, this moment is often treated as the effective delivery date—the point at which the goods transition from the factory's responsibility to the company's logistics team. Yet in practice, this is precisely where lead time planning begins to diverge from reality. The notification that production is complete does not mean the goods are ready to distribute. It means the goods are ready to begin a shipping and logistics phase that can extend the total timeline by an additional four to eight weeks.

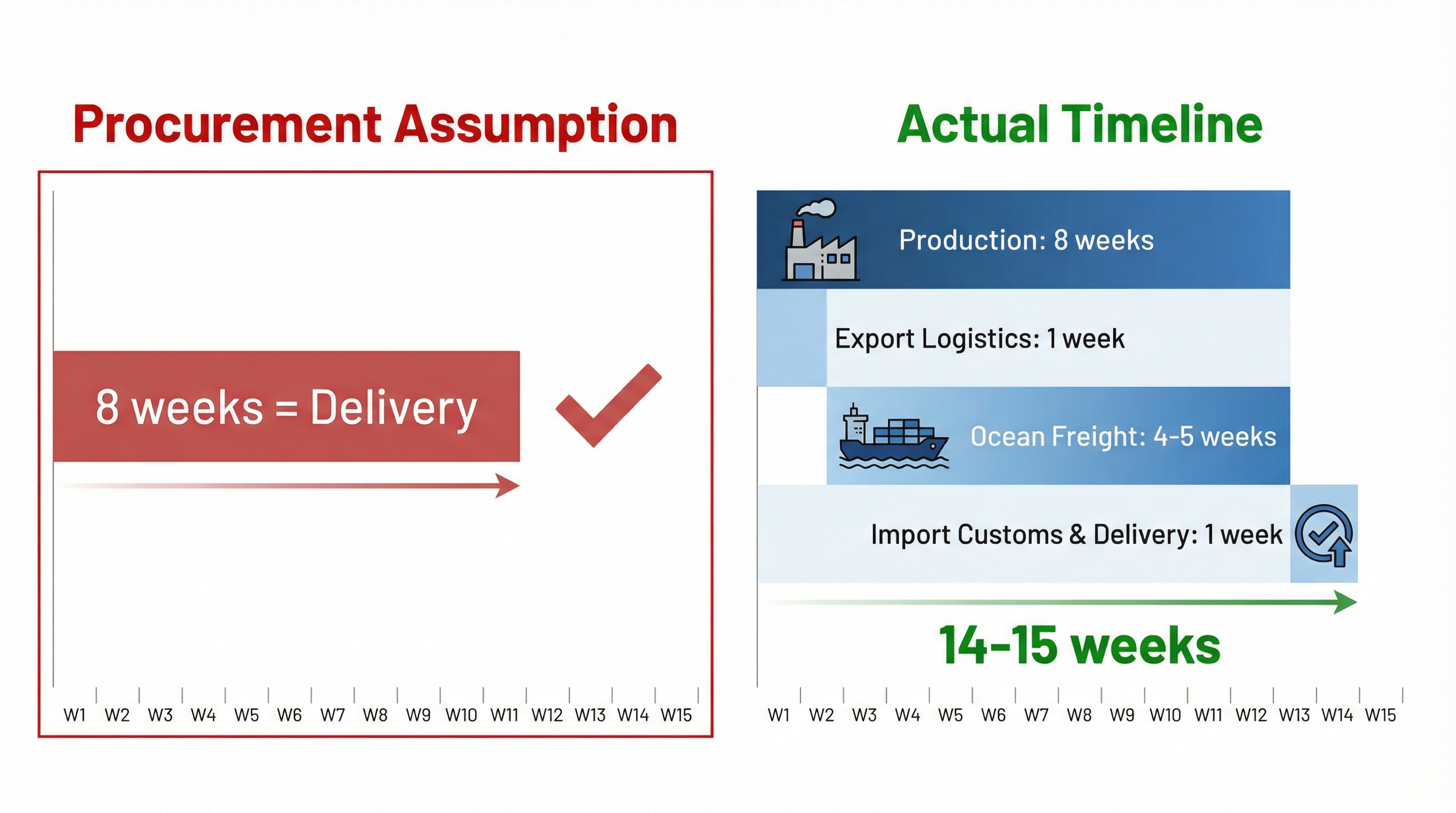

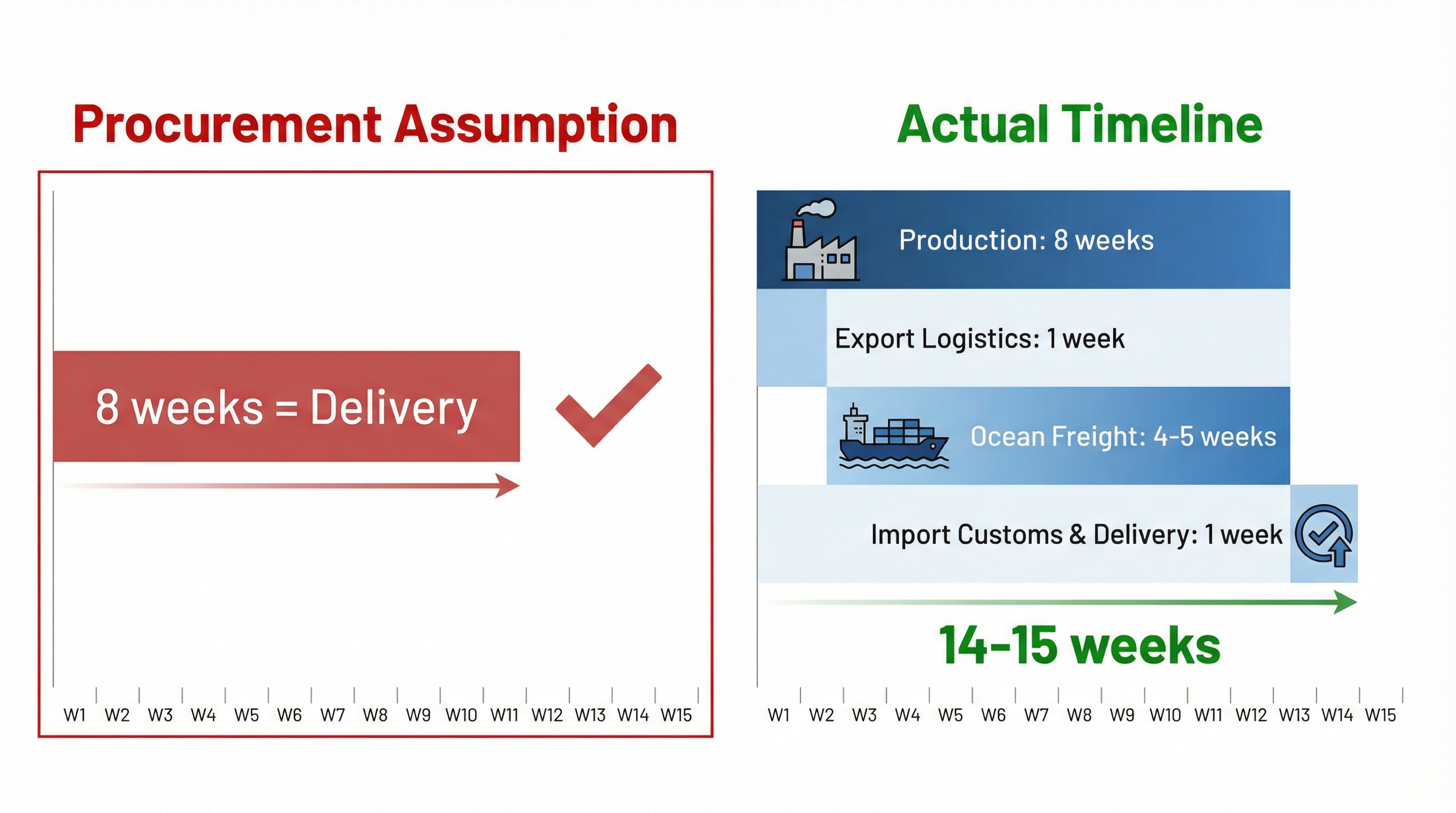

The confusion arises because factories typically provide a single "production lead time" figure when quoting projects. When a factory states that production will take eight weeks, procurement teams naturally interpret this as the time from order confirmation to goods arrival. However, the factory's production lead time refers exclusively to the manufacturing phase—the period during which raw materials are transformed into finished goods within the factory's production facility. This figure does not include the time required to move those goods from the factory floor to the procurement team's distribution center, which involves export customs clearance, international freight transit, import customs clearance, and final delivery logistics.

From a factory operations perspective, the distinction between "production complete" and "goods delivered" is self-evident. Once production is finished, the goods must be prepared for export, which involves packaging for international shipping, generating export documentation, and arranging transportation to the port. In China, this process typically requires three to seven days, depending on the factory's proximity to the port and the complexity of the export paperwork. For factories located inland—such as those in central or northern China—the goods may need to be transported overland to a coastal port, which can add several additional days to the timeline.

Once the goods arrive at the port of origin, they must clear export customs before being loaded onto a vessel. Export customs clearance in China generally takes one to three days for standard commercial shipments, though delays can occur if documentation is incomplete or if the goods are flagged for inspection. After customs clearance, the goods are loaded into a shipping container and placed on a vessel bound for the destination port. The time from port arrival to vessel departure can range from a few days to over a week, depending on the shipping schedule and port congestion.

The ocean freight transit phase represents the largest single component of the shipping timeline. For corporate gift boxes manufactured in China and shipped to the United Kingdom, transit times vary significantly based on the port of origin. Goods shipped from southern China—such as Guangzhou or Shenzhen—typically spend 25 to 27 days on the water under normal conditions, though this figure has extended to 35 to 40 days due to recent Red Sea rerouting. Goods shipped from central China—such as Shanghai or Ningbo—require 30 to 32 days under normal conditions, extending to 40 to 45 days with current routing disruptions. Goods shipped from northern China—such as Qingdao or Tianjin—require 34 to 42 days under normal conditions, extending to 44 to 49 days with current delays.

These transit times reflect only the period during which the goods are physically on the water. They do not account for the time required at either end of the journey to prepare the goods for shipping or to process them upon arrival. When procurement teams calculate expected delivery dates based solely on the factory's production lead time, they fail to account for this multi-week ocean freight phase, resulting in delivery expectations that are four to six weeks earlier than the actual arrival date.

Upon arrival at the destination port, the goods must clear import customs before they can be released for delivery. In the United Kingdom, import customs clearance typically takes one to three days for standard commercial shipments, though this timeline can extend to five days or more if the goods are flagged for inspection, if documentation is incomplete, or if duties and taxes have not been prepaid. Customs delays are particularly common for first-time importers or for shipments involving complex product classifications, as customs authorities may require additional documentation or clarification before releasing the goods.

After customs clearance, the goods are transported from the port to a warehouse or distribution center, where they are unloaded, inspected, and prepared for final delivery. This final logistics phase typically requires two to three days, though it can extend longer if the destination is located far from the port or if the goods require special handling. Only after this final phase is complete are the goods truly ready for distribution to end recipients.

When these phases are combined, the total time from production completion to goods arrival at the distribution center ranges from four to eight weeks for shipments from China to the United Kingdom. For procurement teams that have planned their timelines based solely on the factory's eight-week production quote, this additional four to eight weeks represents a significant and often unexpected extension of the total project timeline. A project that was expected to take eight weeks from order confirmation to delivery actually requires twelve to sixteen weeks when the shipping and logistics phase is properly accounted for.

The practical consequences of this misjudgment are substantial. Procurement teams that fail to account for the shipping phase often find themselves facing missed distribution deadlines, particularly for time-sensitive projects such as employee welcome kits, client appreciation events, or seasonal campaigns. When the goods do not arrive as expected, the procurement team is forced to either delay the distribution event—which can damage stakeholder relationships and undermine the purpose of the gifting program—or to arrange emergency air freight to expedite delivery. Air freight can reduce the transit time from four to six weeks to one to two weeks, but it comes at a cost premium of four to eight times the cost of sea freight. For a large corporate gift box order, this cost differential can represent tens of thousands of pounds in additional logistics expenses.

The misjudgment also creates internal communication challenges. When procurement teams communicate expected delivery dates to stakeholders based on the factory's production timeline, those stakeholders plan their own activities around those dates. Marketing teams schedule campaign launches, HR teams plan employee onboarding events, and sales teams commit to client delivery dates. When the goods arrive four to six weeks later than expected, these downstream activities are disrupted, and the procurement team is perceived as having failed to manage the project timeline effectively—even though the delay was not a result of poor execution but rather a result of incomplete timeline planning.

From a procurement consultant's perspective, the root cause of this blind spot is the way factories communicate lead times. When a factory provides a single production lead time figure, procurement teams naturally assume that this figure represents the total time from order confirmation to goods arrival. Factories, however, view their responsibility as ending when the goods leave their facility, and they do not typically include shipping and logistics timelines in their quotes unless explicitly asked. The result is a fundamental misalignment between what the factory is quoting and what the procurement team is expecting.

The key to avoiding this blind spot is for procurement teams to explicitly request a door-to-door timeline when negotiating with factories. A transparent factory will provide a breakdown that includes production time, export logistics, ocean freight transit, import customs clearance, and final delivery. For a shipment from southern China to the United Kingdom, this breakdown might look as follows: production (eight weeks) + export logistics (one week) + ocean freight (four to five weeks) + import customs and delivery (one week) = total door-to-door timeline (fourteen to fifteen weeks). This breakdown allows procurement teams to set realistic expectations and to plan their distribution activities accordingly.

For procurement teams that do not receive this breakdown proactively, the practical solution is to add four to eight weeks to the factory's quoted production lead time when calculating expected delivery dates. This buffer accounts for the shipping and logistics phase and provides a more accurate estimate of when the goods will actually be available for distribution. For projects with tight deadlines, procurement teams should also consider the option of air freight, though they must weigh the cost premium against the urgency of the delivery requirement.

> Understanding the distinction between production completion and goods delivery is essential when considering the full scope of factors that affect project timelines for corporate gift programs. For comprehensive guidance on planning realistic timelines from order placement through final delivery, refer to our [lead time guide for corporate gift boxes](/resources/leadtime-pillar), which addresses the full spectrum of factors affecting project duration from initial order to final distribution.

The shipping and logistics phase represents a significant but often overlooked component of the total timeline, and failure to account for this phase can result in missed deadlines, emergency logistics costs, and stakeholder frustration. By explicitly planning for this phase and by requesting transparent door-to-door timelines from factories, procurement teams can avoid the costly surprises that arise when "production complete" is mistakenly interpreted as "goods ready to distribute."

You May Also Like

Rigid Box vs. Corrugated Mailer: Which Material Suits Your Premium Corporate Gifts?

A deep dive into the structural integrity, cost implications, and unboxing experience of rigid boxes versus corrugated mailers for high-end corporate gifting.

Foil Stamping vs. UV Spot: Elevating Your Brand Logo on Custom Gift Boxes

A technical comparison of hot foil stamping and UV spot varnish, analyzing visual impact, durability, and production costs for branded corporate packaging.